-

Posts

2,824 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by ruxy

-

-

Probably phrased it badly in reply to Tony B , I find it hard to swing a hammer at the relay body underside when the truck is wheeled - this is why I rely on a pneumatic hammer but I have split one in situ. you can screw a thick round plate on the relay bottom - to bray on. I try to avoid pulling gear as you can easy bend up the X member & the last thing I want is more work than welding a new liner tube in , normally I try and work weeks in advance by squirting diesel down the chassis hole - normally makes things possible.

-

For bedtime reading you need this :-

-

The problem of hitting it with a hammer is being able to hit it in the right direction - normally that is only when the truck is stripped and you can roll the chassis over.

-

It is possible with a fair bit of hassle , even in a vice you may need to make your own spring compressing tool up - so just another modified tool with shorter handle length etc..

There are other issues :-

1. The ongoing problem with certain replacement shafts manufactured from inferior grade of material. Hard to believe that a safety critical part are / were supplied on aftermarket suspect - but that is the case.

2. If water has entered - other parts will be rusted and need replacement, there are often slight size differences on parts pattern/genuine. In fact some pattern relays are designed / built slightly different.

3. Genuine Rover parts expensive (if you can get them) . You may have difficulty getting a OEM / genuine relay complete presently.

4. Probably better and more cost effective to get a new relay unit from a reliable source.

-----------

Relays are in fact quite a loose fit until bolted up - often a new bottom location flange washer is a loose fit on the machined dia. of the relay , people often get a good solid one turned to suite or convert the bottom flange washer to a pinch nut (to eliminate unwanted movement).

-

Good luck with these CD's - I hope you have a very late repaired version (apparently there is a recent patch). I have 3 qty. of these CD's and they are all a problem. There is a legacy problem on newer platforms - they freeze and crash the computer (XP). Most find any Adobe newer than ver.8 a problem with XP - best with a Heritage operating system.

-

You need plenty of "shock" from hammering on the relay cast body - a pneumatic hammer helps. Often the corrosion is the X member liner tube (you will probably find it perforated through) not the cast relay body. The relay spindle is also a shock-absorber against spring loading on Tuffnol cones - so a copper hammer on spindle does zilch. . Probably best to dismantle in situ. (the spring is not that strong - but take care) - water could have entered past the seals and the spring may be rusted up in any case.

Once dismantled - you can play a propane torch on the inner wall of the relay casting , cold shock with water - and then hammer away.

-

NB the bit about post war replacement bodies manufactured by ESKANOR , this name in fact to me does not sound Germanic - more Danish , Norwegion or Swedish ?

-

-

The Phillipines is the place for the repro bodies (as once imported to UK by such as Foley).

The Bemark plate - is that a export plate for such as a Besinger Bemak body ?

http://www.film.queensu.ca/cj3b/Tech/ReproTubs.html

https://www.dlbensinger.com/bemakexcl.php

The rest - the correct description is probably Hotchpotch

-

Yes AFAIK - the two 109" UK registered in BB are the one at Elvington and the one owned by GavinL

Another good photograph of it with trailer in BB

http://forum.emlra.org/viewtopic.php?p=24605&highlight=#24605

-

More photographs , ISTR there is another UK registered 109" in BB that is not the one at Elvington - need to do more searching.

http://forum.emlra.org/viewtopic.php?t=1752&highlight=berlin+brigade

-

ISTR they are to stop a 9' x 9' tent blowing away

-

Hard to say , the removal of lead was pushed through too quick.

The FBHVC more or less collated results , chemical additives are here (bottom of link) :-

http://www.fbhvc.co.uk/fuel-information/

A few more such as Wynns & Texaco introduced products but I have never seen any update on FBHVC website - the best type to go for , Castrol & Millers apparently.

-

What do you believe , where do you start. First find if a Mr Henry Broquet was in the employ of the RAF , what was he a specialist in , did he go to Russia. I suppose if you are so inclined - you could search records held by the RAF

-

Carbonflo

Fuelcat

Broquet

etc.

It keeps surfacing.

So is there any sound evidence that a person by the name of Henry Broquet of the RAF did in fact go to Russia during WW2 and sort out inferior fuel making it suitable for use in Hurricanes ?

This seems to be the starting point but apparently he improved the catalist later when in South Africa, I have my doubts about any truth in the story.

-

Thanks - as suspected. Are they readily available ? - also what sort of asking price ?

regards

-

The above are used with the Land Rover Lightweight "Unitary Radio Kit" and are for spilt acid protection for UK6TN No.4 Mk.3 batteries (to FV.546133). Whilst washing down these GRP containers for a fibre-glass to cracked corner I noticed the yellow markings stating :-

BATTERY CONTAINER FV.546185 No. 4 Mk.3

=========

Now I understand these UK6TN are also used as starting batteries on armoured FV's ?

Just wondering - are these containers part of the common parts bin and used on other vehicles or are they specific to the "Unitary Radio Kit" ?

I have had a bit of a Gooogle around on FV546185 but found nothing of interest !!

Thanks in advance

-

Plenty of good photographs of exactly what you need in this book :-

Unfortunately due to high demand by the modellers it has status , high prices can be asked by book dealers.

Don't pay more than £15 to £20 for a minta , bide you time watching eBay - they do come up.

-

I have 6 qty. FV.2361 narrowtrack inc. a brand new one built in last contract abt. mid-1970's (these did not have the drain cocks) - just a hinged flap on the transom (apparently for different reasons than on the widetrack hinged tailgate).

I only have one widetrack FV.2381 , a Mk.3 Reynolds Boughton KK - so OK in period for behind a KG 90".

All I can say is that IMHO the widetrack looks badly out of proportion behind a L'wt.

Unfortunately I know little about the trailers in between (widetrack Mk. 1 & 2)

There was also the odd widetrack by KING but I have only seen a photograph of one (Marcus Glen had one for sale , it had KING impressed in the tailgate in huge letters).

Apparently lots of Paratow around but little rivet counter info. known about them.

I have little / nothing in way of widetrack info. / parts lists (must obtain) .

I understand the widetrack earliest manuf. to be from about 1978 , correct wheelset for Mk.1 - I don't know ?

I was reliably informed that as such there were no Mk.2 manufactured as such - the Mk.1 was subject of so many mods & X strikes on the plate that when they finally decided what they wanted they manufactured and named as the Mk.3

No doubt there will be somebody far better informed about widetrack on the forum than I am.

-

WIDETRACKS IIRC :-

Arrow Const. Equip. only made the Mk.1 - so drum brakes & early draught.

Mk.2 were up-graded Mk.1 ISTR this was to Mk.3 spec.

----

Mk.3 (disc braked)

Built by :-

1. Reynolds Boughton

2. Universal Engineering (South Dorset Eng.)

3. Viking Trailers

4. Parotow

-----------------------------

Unless you are desperate for a original drop tail-gate , you don't want one behind your Lightweight , you need a easy to single man-handle narrowtrack. Get this point wrong and you will regret it , the front jocky wheel is no great help.

They have 7.50 tyres - so you can't use your vehicle spare.

They are more in keeping with TUL/TUM for size and operating era.

They look horrible behind a Lightweight and get in the rough they are too wide to follow through your vehicle tracks.

YUK in most respects - in the main problems getting disc caliper & master cylinder spares.

-

There are few Lightweight Wombat Portee photographs available , 3 or 4 good ones in this book :-

http://www.amazon.co.uk/Half-Ton-Military-Land-Rover/dp/1903706009

Save your money for a few weeks as it is in re-print and then the sensible price will be about £20

-

Idi Amin would pay good money for that lot

-

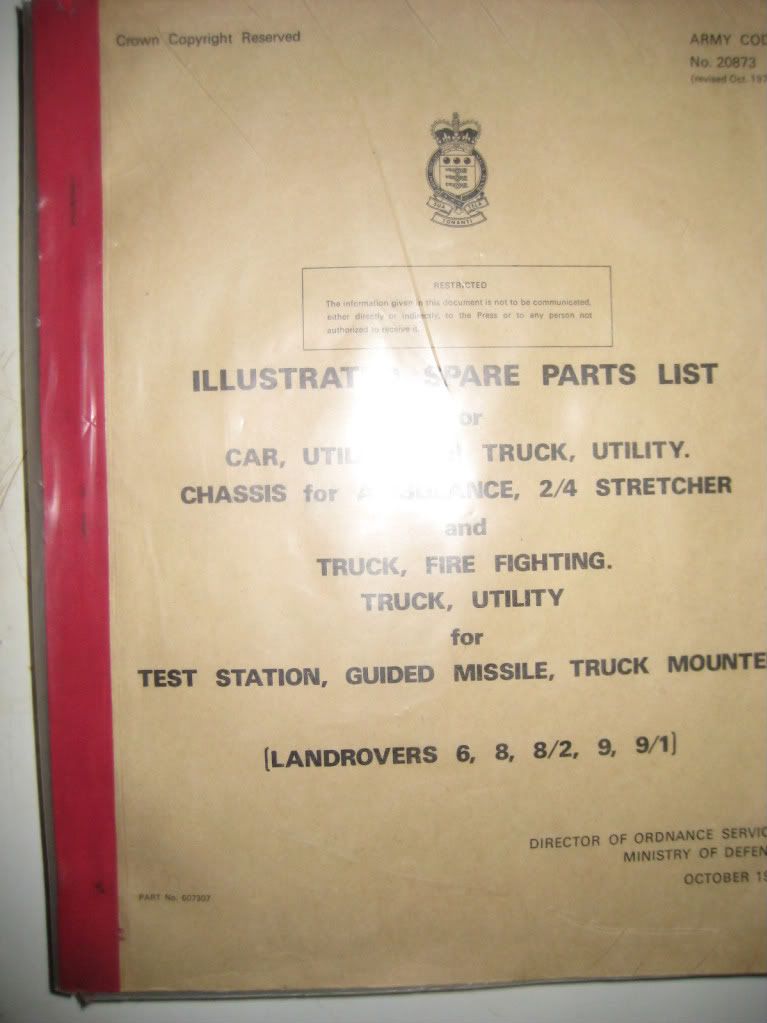

Off hand I can't tell you the difference apart from the different Asset Codes. I'm looking in Equipment Regulations for 1963, 1964 & 1967, they've got Rover 8 & 8/2. But no 8/1 but I suspect they were upgraded to 8/2.

Although I note there is Rover 9 & 9/1 but no 9/2. Anyway I mustn't go digging up the documents that could take an hour or so, must get out into that sunshine!

==================

Not wishing to get heavy into comparison of spare parts lists , ISTR the main difference between 8 & 8/2 + 9 & 9/1 is that the 8/2 & 9/1 have reinforced Rover axles

-

From the Rover 11 list of contracts , WV10634 - Item 1 seems to be CTS CODE CO(1)

CHASSIS FOR AMBULANCE , 2/4 STRETCHER, 109 in. wb. RHD

0n N.S.N. (Nato Stock No.) 2310-99-808-1472

For Army service. 12 volt

FOR DETAILS OF BODY SEE ARMY CODE 22147

I suspect Marshall of Cambridge possibly branded B/21 as their suffix.

Para light weight

in MV Chatter

Posted

Probably the best details of a genuine recce L'wt is the one belonging Rogan (search through all his postings) on Ex-MLRA , there are photographs of the extra bracketry on chassis for the special shelf tailgate. This recce is shown when in service in Mark Cook's book.

http://forum.emlra.org/viewtopic.php?t=5047&highlight=rogan

http://forum.emlra.org/viewtopic.php?p=33228&highlight=#33228