-

Posts

2,825 -

Joined

-

Last visited

-

Days Won

16

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by ruxy

-

-

Yes , BGS as explained previous.

Have a good read of this thread :-

http://www.series2club.info/forum/index.php/topic,44023.0.html

Earlier truck but a great deal of info. - True S2 is German and has gained all museum info. etc. He has obtained it seems all the specialist radio equipment too.

I did not know the that BGS had any so late as Rover 10 and your truck is in great condition AND seems to be a genuine Rover 10 (late) , I think the winch is original too ..

-

Hello Ruxy, I have just joined HMVC and was browsing the forums to try and and find out what LR I have just bought. It is a 1970 series 2A with headlights in the wing and 24 volts with an awful lot of electrics. It also has connections for batteries in the rear. I do not know if it is FFR or not. Is this what you are looking for? If so I will take more photos including the plate and send them to you. Regards Paul[ATTACH=CONFIG]62107[/ATTACH]

Yes , if you could post a few more photographs , inc. if extant - the nomenclature plate showing Contract number etc.

A late Rover 10 , 88" would look very similar from front (without winch) , it would NOT have the plastic finisher trims around the headlamps as military FV headlamp units were fitted.

-

I once found a burried tank in my back garden , a brick bunded steel oil tank ! The PO had gone to a steel surface gravity tank when the lift pump had failed , this tank eventualy rusted through on the underside. During removal of this tank (to replace with two plastic tanks) - I found a big concrete slab that I considered may be a WW2 bomb shelter - so started hacking away through the steel reinforced roof LoL , then I discovered that the bund extended under and supported in part the rear conservatory LoL - so it is there to this day. I also discovered the PO had built a rockery over the tank vent mushroom cap - so the kero fumes was vented , unfortunately when I used a dip-stick the tank seemed empty.

-

Sand sea , covered / uncovered my moving dunes - but then it should be full of sand. I would have expected the paint & instruments etc. to be more sand blasted after 7 years - strange ? Must be in a area that has little / no wind ?

-

-

You need something that is "free-cutting" for machining relatively easy without tearing. Not something too cooking such as Leadloy that is basically a En2 (low carbon).

Such as En6 or 6A - the maximum carbon is 0.4% (into "Medium carbon steel range".

En5 is supplied in normalized,or hardened & tempered (you need to avoid post heat-treatment).

The property letter basically indicates the strength (derived from heat treatment).

IIRC - starts at M , but lowest commercial is probably P

going, Q. R. S. T. U. V. W. X. Y. Z

Z = 100 tonf / in2

For a wheel lug nut that is deep - then P is more than adequate , the threads will be quite tough , the case will be tough to prevent spannering / socket marks , you don't want anything with hardness as there would be a danger of shear at the thread roots.

I have been out of all of this a few years now, at the end of the day - you will have to see what is available in hex. stock bar to greatly reduce machining costs, a good steel stockist should have comparison tables as you could find the same stuff under other ref.

-

BS. 970 En5. (30 carbon)

P condition @ 35 tonf/in2 is sufficient

---

or near equiv. such as 6A

-

-

Chamois leather gaiters were also listed in the Civvy Optional Parts Book. The MOD had them fitted - even on CL's (commercial logistics / civilian spec.) - they probably had run some trials. Probably better with, depending on environment , does not take long to unlace & clean out any debris & wipe some thick tacky oil over the chrome balls, if needing cleaning often - then better without. The kit supplied Jubilee clip - use a stainless steel one - better for removal when cleaning.

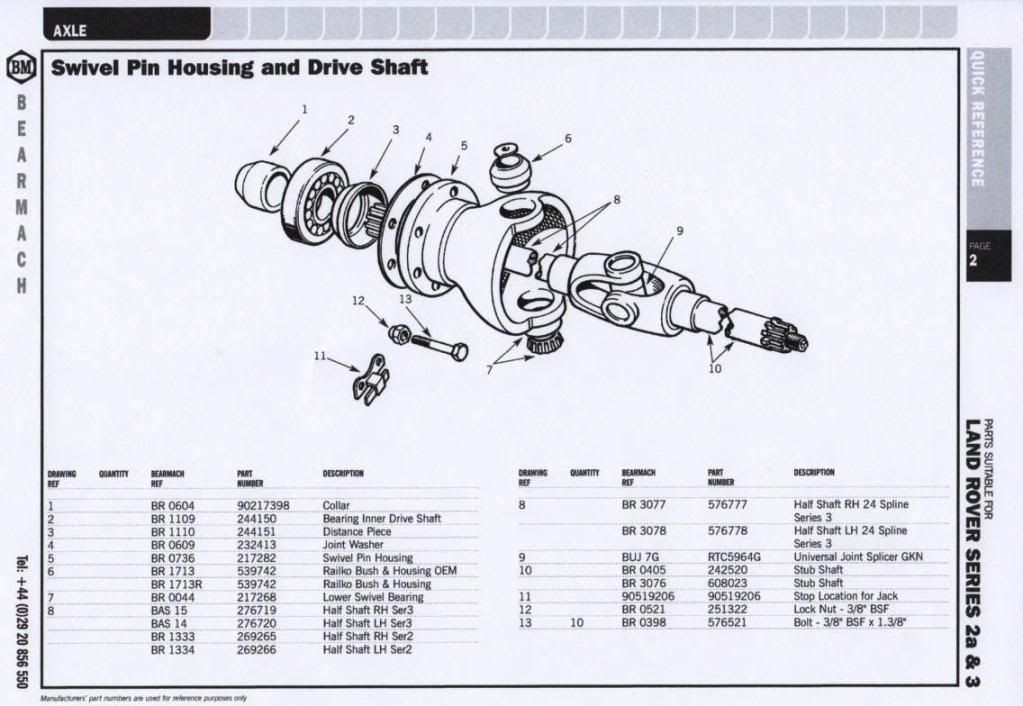

IMHO stick to oil lubrication, Series 3 (earlier had top compression spring/cone & most now later upgraded , you would have to be a rivet-counter - daft as they are not seen) have the Railco material top bush as it is better than the sprung cone. However they do need occasional soaking with oil , arguably the coiler (Defender etc.) lubricants don't do this well. IIRC coilers have a top bearing. The periodic oiling is the requirement for a periodic engagement of free wheeling hubs - so stub shaft is rotating & joint splashes the oil around & up to the Railco material.

-

-

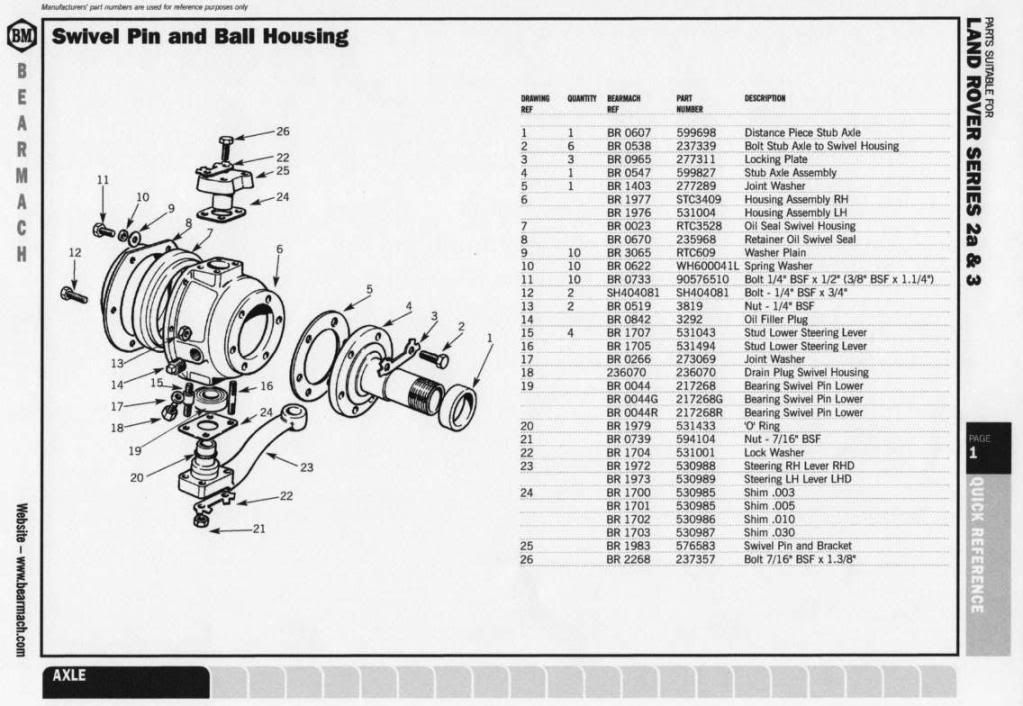

btw - leave the studs in the swivel housing , only extract if threads badly damaged - they are set with thread-lock to prevent oil loss on your drive LoL

-

Be aware the lower steering arm (or upper steering arm on such as a earlier S2A) , the double threaded boilts (studs) - each arm is secured with two studs having slight clearance to the holes , the other two are a slight interference/transition fit to positively locate & secure. So each housing needs 2 qty. 531043 (IIRC the fully fitted studs) & 2 qty. 531494 (IIRC with clearance).

Often a copper mallet job to tap the leverage off the dowels.

The small set-bolts are often the bigger problem , they can easy strip the threads in the cast housings if you try to drag them through with rust on the threads.

-

Hi Folks, I am trying to establish the date of manufacture for a Land Rover, chassis No. 25121816H. Any help would be appreciated, thanks.

====

What you don't state is if it is a civilian 109" S2A or a military. Different rules apply. If military - defo a Rover 11 (headlamps in wing panels).

Military 109" 251prefix at end of Rover 9 production are only up to Suffix C , unfortunately I am short of the Chassis range numbers for Rovers 10 & 11

-

Possibly - I suppose, but that would mean 9 years to build 21,816 qty. 109" , ignore me - there are people who make a hobby out of this type of info.

LoL

-

S2A started Sept. 1961

251 = 109" w.b.

So - the first off would be 25100001A

Suffix A , is as built at Sept. 1961

You have Suffix. H , this means 7 qty. substantial design changes after Suffix A

You are seeking build date of the 21,816 off the line

Now - I don't have any idea of the production rate.

However - I would guestimate at 1962/63 , not based on numbers - more on the fact that ISTR most production changes happened in 1962/63 - then few changes until the major changes abt. 1976

-

That would be the UK Border Patrol Rainbow Warrier making its appearance ?

Sorry - just noticed , you are Dutch LoL

-

-

Hi Dave

-

QUOTE from The Daily Telegraph

Mr Cundall said: “We sent a borehole down and used a camera to look at the crates. They seemed to be in good condition.”

----

So - probably what he used was something costing more £ than this , thus better results (probably logged on a loptop - must have done) :-

http://www.wildlife-cameras.com/index.php/Probe-Camera-Kit/UNDER-GROUND-CAMERA-KIT.html

The man states - "They seemed to be in good condition" , just have to accept what he says and remain patient, pointless speculating.

He may even read this and give us a exclusive pre-view.. WoW

-

Look at the code on the label :-

H1/8010-99-224-5482

Probably Clive Elliott will be able to reveal more , I don't know - to me it looks a early NATO type SC.

I do know from where / whom I used to obtain that particular paint. He had some very good connections and in fact a small fleet of WW2 restored vehicles - they were re-painted with it. I seem to recall watching him one day with a rag rubbing engine oil on the surface of a Jeep that had been re-sprayed a few years prior ( authentic , in-service distressing). Of course 1 gallon could be purchased off him for £5 cash. when 1 litre of re-finish would be over £10 , probably every show truck in NE England was glammed by same stuff / means. IMHO there is presently too much rivet-counting on finish coat , encouraged by forums LoL ,, not helped by lack of "quality" solvent based time-expired Ex-MOD paint or genuine manufacture factory sale (blame the Solvent Regs) , . Most of the stuff now on eBay is a rubbish cheapo alkyd - hardly suitable for a good resto. - where you would be better having machinery / Fleet enamel mixed to spec. & take your chance on shade with the RC'ers.

-

-

I wonder whick Mk. Spitfire / Seafire ?

http://www.guardian.co.uk/world/2012/apr/14/david-cameron-spitfires-buried-burma

-

Good buy !!

-

Looks like you will have to pay abt. £25 for a B card search at RLC Museum. Seems in your case early history not transferred onto Merlin computer , sometimes it is.

I have come across this before , check for VPK having been fitted. Extra holes in bodywork, best / easiest - look for a hole abt. 12mm dia. centre very rear of tub (where bottom of lower tail-gate sits) for engaging bi-parting centre doors shot-bolt. It seems that quite a few were fitted with VPK and held back as reserve for years at OSU Thetford - some never reached NI..

No. 138

in Clive's Mystery Objects

Posted

Contains potential sparking equipment for use in a explosive environment - the spark is quenched by the perforation holes before it escapes and blows the munitions factory up ..