-

Posts

11,492 -

Joined

-

Last visited

-

Days Won

46

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by Richard Farrant

-

-

Terry,

I recollect one of my customers having a problem with one of those switchboards on a Saracen when I think a screw came loose inside. might be worth going to the tail lights for starters and isolating the feed wires and see if it is still tripping.

-

I am assuming 'flatfront' refers to the appearance of the bonnet and you are asking about rear axles?

MW, OX and OY rear axles are all different. The MW and OX are similar in design but the OX has a larger diameter diff carrier due to larger crown wheel. The OY has a stronger axle casing without the tin cover (all cast). Each one has differing ratios. I would think it possible the MW axle could be narrower than an OX.

-

What about Grundon's Pierce Arrow?

-

There is a FWD Model B on auction in Australia at present, bidding starts tomorrow with an opening bid of $9. Looks like it has pneumatic tyres fitted. The Australian War Memorial are disposing of it.

-

Has anyone done a modern beadlock system to retain the runflat capabilities?

The only way to make your chosen tyres (Michelin?) with a runflat capability is not a beadlock on its own as that will be useless, but to have a Hutchinson runflat insert put inside the tyre. We had these on the CVR(W) Fox armoured car when they changed over from Dunlop Trackgrip RF to Michelin which was basically a normal truck tyre. The insert is like a thick rubber ring that is inflatable, it will hold the tyre in shape if punctured, ie bullet hole and allow the vehicle to be moved to a safe area to deal with the wheel. It is also a beadlock in itself. The Fox had 1100-20 tyres, no idea if the inserts are available for 900-16 but worth investigating if you wish to go that way.

-

Hello all, my Leyland Martian steering tank states OM13 mineral oil is to be used but someone prior to my ownership has marked on it that OM33 oil is to be used, now are either of these oil types suitable for use with a more modern power steering pump - namely from a 1993 Cummins C series engine or will the more modern seals in the pump not like it ?

Cheers Chris

Chris,

OM13 and OM33 are both army designations for hydraulic oils, the number roughly translate in to ISO viscosity grades. OM33 was the general hydraulic oil in army plant, it equating to the normal 32 hydraulic oil used in civvy street. The OM13 is an exceptionally thin oil. I would suggest you use the type of oil that suits (or is specified) the pump on the Cummins engine. I do recollect the power steering on some AEC lorries had engine oil in it.

-

A few queries along these lines, if I may.

3. The other option is an electric pump in the same position as (2) - I guess a 12V pump is suitable, rather than 24V? However on Googling the warning is to wire it so that it stops pumping if the engine stalls. The tachometer circuit is one suggestion and it certainly seems sensible to not keep pumping fuel if the engine stops for whatever reason, but this is getting a bit complicated for me. You'd hope that the carbie would stop fuel flooding everywhere but I'm not sure.

Using the tachometer to switch off the pump will not work as it is cable driven ...... not electric.

-

Not RR B Range, the military distributors have the points on a Bakelite base and contacts are orientated different to this one.

-

Hello folks,

I find the level of the SAE 30 straight to be very hard to read on the Ferret dipstick for the gearbox. There's very little contrast. A friend said he used to use green Duckhams SAE30 to improve matters. That'll also help diagnose things if the oil bleeds through into the transfer box for any reason.

Does anyone know if you can get suitably coloured oil, or if there is colourant that can be added?

cheers, Mad Scientist

hi,

you are thinking too deeply on this one! As someone else said, just lay the dipstick on a piece of paper or the back of your hand and you will see immediately what the level is. Another way is to black the dipstick, either a flat black paint, stove black or similar and you may find it shows the oil up better than a natural finish metal.

-

On the mark 2 you can remove the centre bevel boxes before the transfer box

but you need to remove the front and rear pinion cases first.

not sure if mk 1 is different though

Yes you are correct, it has been about 30 years ago when I last took bevel boxes out of a Stalwart and my mind was foggy. Getting the sleeves back off the drives shafts can be difficult too if they are seized, but they need to come out before you can remove the pinions on the bevel box.

-

Can you remove the centre wheel stations and then try and pull the centre bevel boxes out through

the hull until the shafts clear of the transfer box?

in my head it works but may not in practice .

You have to remove the transfer box first before you can remove centre bevel boxes.

-

Good grief man ........... its got a Rolls Royce engine, you can't put a godamned Ford in it :-(

For disc brakes you would have been wiser to have found a Mk4 Ferret, which has discs all round and parking brakes by way of band brakes on the internal propshafts. I think the 16 inch wheels did not give enough clearance for the caliper and they used 20 inch wheels.

So are you going to still use the Wilson pre-selector gearbox and fluid flywheel? It will take a bit of engineering to match that up. Below is a photo of a Mk4 Ferret if you have never seen one:

-

The axle type was used in series 2 and 3 trucks (and series 1?) and all the Austin based BMC and smaller Leyland trucks e.g. WE, WF, FE, FF etc. I didn't want to say too much as there will have been variations so it doesn't follow that every one of those trucks will have an identical half shaft. It seems to me if the number was cast in the flange it might not be the proper part number for the shaft though.

It could well be that the number is for the original blank forging and there could be variations in the final machined part, but it is something to look for if going to a scrap Austin or Morris lorry of that period.

-

Seem to think I have read this vehicles history before. I think that it should read 'RE Diving' and therefore if going on a diving emergency the two tones and blue light would be needed.

-

Land Rover Series 1 86" originally used by the Royal Army Ordnance Corps.

Brightwells' Leominster Classic & Vintage,

Noon, Wednesday 27th September 2017.

The catalogue is only in alphabetical order at present:-

It would have been delivered to the army Vehicle Depot which was run by RAOC. Reading the history board in one of the photos, I see it was bought by an old acquaintance who was in REME, lost touch with him some years ago. Nice looking Land Rover.

-

I don't think it would come to that. I may be wrong, but the same type of axle was used in at least some of the Series 3 trucks, which later became the BMC and Leyland range, so I'd have thought it quite likely that several of those used the same shafts.

Where on the shaft is 11K 7895 marked?

That is what I was suggesting, a lot of commonality in those days and the Austin S3 multifuel was a short production run. The number was cast on the outer face of flange, from earlier photos.

-

Looking at this photo of a 3 tonner (ie long wheelbase), it looks like the leading mudguard for rear wheel is under the centre upright on body side, whereas the lorry in the film appears to have the centre of the wheel under the centre body upright. This was how I came to the conclusion it was a 30cwt in the film, ie shorter wheelbase. Could be wrong though :undecided:

-

Can anyone ID what type of 30cwt truck it is, shown in SCC2 and black camo?

The truck appears after about 7 mins 40 seconds

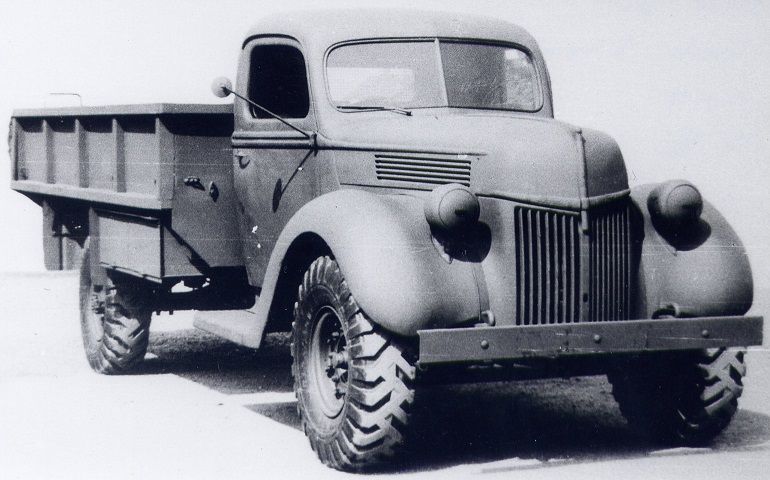

Think it is a Ford E018T 4x2 30 cwt

-

This Lanc flew in to Adelaide domestic airport late 1962 , then it flew out again.

The black exhaust trails under the wings would normally not be visible against the wartime black livery. Was the Merlin running rich ?

Source: http://www.goodall.com.au/photographs/adelaide-airport-visitors/ADELAIDE%20AIRPORT%20VISITORS.html

Mike,

i would say the exhaust trails are normal but showing up more on the white wings

Richard

-

What type of carburettor(s) , if SU - could be a dashpot oil issue.

According to my carb book it should be a Solex 35FAIE

-

If you have the shells you could get them remetaled.

Thanks, yes I am aware of that having had to do it before, but there are other options available too.

-

Hi Richard,

I have Cadillac main bearing set std,mine are for Stuart.I've recently supplied some parts for an oxford carrier restoration.i don't know whether this is what your working on,as apparently no good for that engine.

Regards Simon wilkinson.

Hi Simon,

Thanks for responding, I am sending you a Private Message on here.

regards, Richard

-

Hello Richard, in a sense yes as we removed all of the sun gears from each hub so that we could tow it into place

Hi Lewis,

See if you can turn on of the driveshafts which go between bevel boxes, a big set of pipe grips might help, also, make sure transfer box in in Neutral position, the less you have to turn over the better, assume handbrake is not on or dragging.

-

Hit a bit of a wall with the Stolly chaps, I'm having a real struggle removing the centre bevel box clamps as our transfer box is locked solid for some reason so I can't turn it to line the clamp bolts up with the inspection holes. With securing nuts removed, side upper bearing caps and the big adjuster clamps removed I assume the big cast front cover should pull off? I'm struggling to get ours to budge so that I can see what is going on in there!

You have all the wheels off the ground? Do you have the EMER covering this task? I advise you to get hold of them as it saves damaging anything and the drawings do explain the construction of it.

Is anyone's ferret currently equipped with run-flat equipment?

in British Vehicles

Posted

Are you expecting to go into combat with your Ferret?