Sean N

-

Posts

1,497 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by Sean N

-

-

-

Clive, I think this is the Mk2 version of the FV2500 but of course that doesn't make it the same.

There's quite some discussion of the different variants here, in which you posted a photo of the binned stores version of the Rubery Owen trailer:

http://hmvf.co.uk/forumvb/showthread.php?2991-Just-Had-That-Dreaded-Call-from-Withams

-

Can anyone definitively identify a set of four Rover pistons, part number 246346?

They don't come up in Rover parts lists, perhaps because the part number is for the set and individual pistons might have a different part number?

I have seen these listed as for Rover 60 and Land Rover Series 1 2 litre engines but variously for 1952-1955, 1954 - 1955 and 1954 - 1959. I'd like to eliminate the confusion!

Thanks.

-

Originally 90 EP but 80W-90 EP will be fine. My preference is for GL-4 if available, it'll be OK with GL-5 though. Must be an EP oil as it's a hypoid diff.

-

Colin, the main the with an MJ is to keep the rot out of the cab. Cab gutters / roof seams, door bottoms, footsteps, front lower quarter panels, window and screen surrounds, cab mounts, floor areas and box sections, access hatches and wheel arch seams - in fact, pretty much every seam - are all areas to watch.

-

First check if there's excessive lash in the diff by the free play (rotation) in the prop. Also check whether there's any detectable play in the pinion shaft bearing by trying to move the prop / pinion shaft radially - the bearing is preloaded so there shouldn't be any radial play.

Might be worth just jacking it up and spinning the wheels by hand to check for wheel bearing problems, but really you'd expect that in two or four wheel drive.

Also, if you're not sure where the noise is coming from check the transfer box for bearing problems, again by pushing and pulling on the props to see if there's any play.

Check all oil levels as Richard says.

Popping the cover off to check the diff is a five minute job. It's a cork gasket which might tear if it's been on there a while, so having another gasket ready might be an idea. Look at the crown wheel for excessive wear and correct meshing marks.

Don't be afraid of it, they're a simple axle to repair if there is a problem.

-

Some of the bits that are left, in case they're any clue:

-

Thinking about it, the way German abbreviations and acronyms work could Zerstörkörper F. Z. mean Zerstörkörper FlugZeug, which would confirm what I though about aircraft demolition charges?

-

Not just that - Sprengstoff means explosive.

WASAG was a major German explosives manufacturer for civilian and military purposes; by WW2 it was part of IG Farben.

I can't get a good translation for zerstörkörper but zerstören means to demolish, ruin or destroy, which would make zerstörkörper 'demolition body' so I think it's likely these were 3 kg demolition charges.

Edit - In fact, further searching German results for zerstörkörper mainly throws up results for Luftwaffe documents, including several pilot's handbooks; the FW200 'Condor' handbook says:

"For destruction of the aircraft in appropriate emergency, 2 brackets are mounted under the navigation table on the left for a single 3 kg [zerstörkörper]"

As to how it got there - someone needed a handy crate for their posessions on return after the war?

-

Don't know to be honest, Clive. I've only ever seen the FV2500 series designation applied to the earlier version, the Mk 1, and it's so long since I've been under one I can't remember what the brakes are like.

I have an ISPL for the Sentinel Mk 1 but Sentinel and Rubery Owen are quite a lot different (though the shoes, bisectors and adjusters look the same, but then there are a lot of similar looking ones that are dimensionally different so I'm not relying just on appearance).

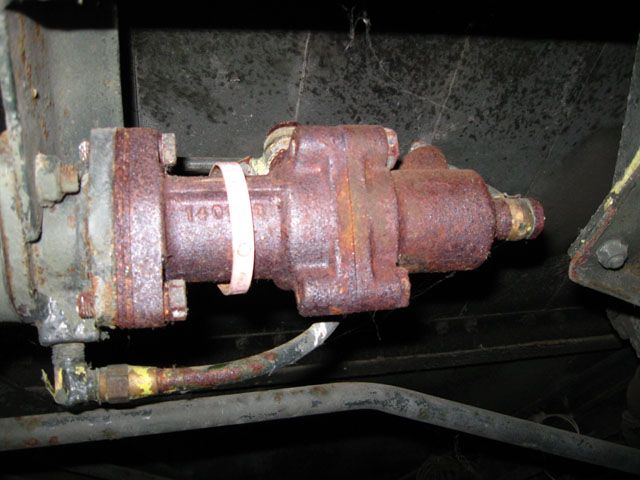

The trailer I have has air actuated hydraulic brakes on the front axle if that helps, with external slave cylinders marked FV506015. If it sounds as though they might be right I'd be interested to see them.

-

All,

I have an Office, Trailer Mounted, 2 ton 4 Wheeled Rubery Owen Mk 2 (wide track) 6240-0735 to contract WV5478.

It's in really good condition but unfortunately the brakes had been cannibalised from the front axle before I got it.

I'd appreciate any pointers for new brake parts (shoes, return springs, actuators, adjusters) or the correct parts list so I can give people some part numbers.

Thanks.

-

I have some of these thin spanners in Snail and other makes, right up to the present day. As Richard and Ruxy suggest, useful for locking nuts, pipe unions, adjusters in awkward places, or anywhere where there's a reduced height fastener and a component or other fastener a full thickness spanner might interfere with.

-

Ah, Sean, you fell for my tease! :-D Yes, the photo is 'small', the Bedford could be, as you say though as I've not shown a Homs-based Bedford yet, 'we've' not seen it before on here. What makes you think it's an early cab? I thought you'd need a frontal view to establish cab type (hi/low headlights, radiator cowling cutout, grill, logo etc. There looks to be a hip ring gun ball mount, but I could be seeing things. Do please tell more about the cargo body types, early and late.

Well, only slightly. I thought you were teasing but thought I'd go for it anyway - and may have been teasing you back!

The high headlights were only in the very, very early vehicles - the lights were dropped quite soon, and many earlier cabs have low lights (counting 'early cab' as the type with the solid upper grille panel, rather than high vs low headlights). See your photo of 35 BR 68 on the first page.

I'm guessing an early cab for two reasons; partly because it doesn't look as though there's a lip round the upper grille (though it might be in shadow, and really the photo's too small to tell anyway) but mainly because in '58 / '59 the later style with the mesh upper grille would have been fairly new, so there's a higher chance that it's the earlier one!

You will now no doubt produce a photo of the same vehicle clearly showing mesh grille and winch fairleads.

I certainly don't have dates & changes for cargo body types on 3 / 4 tonners and my knowledge is by no means definitive, but my understanding is the type shown with four panels and two rows of tilt hooks is earlier, whereas later vehicles typically have a split drop side (so you can drop the front or rear half) with six panels, three on each half - see this photo of 50 EL 82 on Miliblog: http://miliblog.co.uk/wp-content/creativegallery/readers-photos-raymond/bedford-rl-3ton-cargo-50-el-82.jpg

-

Difficult to tell from such a small photo, Lizzie. I'd hazard a guess that it's an RLB or RLD so without the winch, and an early cab (and body). Might even be one of the trucks featured earlier in this thread?

-

those 16 r's are popular at the moment.

hope you get your box sorted soon.

Always the way. I had three for sale last year, here, on eBay and Milweb and couldn't give them away.

-

No prizes for guessing the correct make and model number

Truck 3 ton 4x4 GS Bedford RL.

Oh, sorry...

-

The shape of it, it's clearly designed to clamp something round or tubular. Given the classification it might be tempting to think it's a barrel, but it could just as easily be a trailer leg or stabiliser.

-

In the 1991 issue of Defence Standards, OX-8 was to spec SAE J1703 which is DOT3, but I always use DOT4 which is to SAE J1704

Richard, that makes sense; I don't have a later Def Stan either, but I suppose one might have expected it to be updated to DOT4 as DOT3 is now somewhat obsolete.

SeanThat's why I posted the question, following research online and the horror stories I thought I would ask the question of those with more experience of working on vehicles than me.

Knowing my luck would buy one off the shelf and find issues once it went in the system and then have to strip out all the brake lines and renew them

My understanding is that DOT3, DOT4 and DOT5.1 are all PEG based fluids and can be mixed safely. DOT3 is somewhat old fashioned and obsolete these days.

In recent years synthetic DOT4 and DOT5.1 formulations have appeared, but just as with synthetic motor oils, that doesn't change their compatibility.

DOT5 is the silicon brake fluid and can't be mixed with any others. A lot of people moved to it when it came out because it's not hygroscopic, but it turned out it had a lot of other issues and is probably best avoided in standard braking systems. The horror stories you report might be to do with DOT5.

I've seen suggestions that DOT4 might not be compatible with seals in certain originally DOT3 systems because of the ester content. Some of the brake fluid and brake system manufacturers recommend sticking to the fluid originally specified for that vehicle in case of compatibility issues, as system components will have been designed to work with the mix of chemicals in use at the time. In general that's a good principle to use; having said that, I've never actually come across any problems despite many years working on vehicles.

When I started driving DOT3 was pretty much standard; I was doing a lot of motorsport at the time (getting brake discs glowing orange with use), moved to DOT4 for the higher specified boiling point.

I haven't heard any horror stories about DOT4 vs DOT4 synthetic, but then I've never chased them online. I suspect the horror stories might be to do with DOT(x) vs DOT5.

I would have thought if Penman specify synthetic DOT4 there's nthing special about it and you could probably get any synthetic DOT4 from the motor factors and it will be fine, but this is only my opinion - the usual disclaimers apply.

It's likely the brake system was not made by Penman but by Lockheed, Girling, Lucas, TRW or one of the other brake system makers. If you're still unsure, you could go to them and ask.

-

Clive, John, the NSN has been mistranscribed. I think it reads 3026 (not 5026) but on one label it's been written as 205 and on the other it's 250, so either -99-205-3026 or -99-250-3026.

On the ISO Group site 1095-99-250-3026 doesn't return a result but 1095-99-205-3026 does, and it crosses to MEXE C33811; though rather unhelpfully it's just called BRACKET ASSEMBLY which doesn't tell us more than the photo does!

-

I always thought OX8 was just standard mineral brake fluid to DOT3, and later DOT4, spec - nothing special. Is there any reason why you can't just buy a bottle of DOT4 off the shelf at the local factors, or am I being naive?

-

According to Clive's lists, W8 is EOD equipment, while 1095 is miscellaneous weapons...

-

Rob, ya got a PM.

-

Neil, if it's a 6x6 someone's bent the front axle and stolen the diff!

Not sure what he's after for it - open to offers, I think. Give me a shout if you want to discuss further.

-

Just seen it, Rob. Mark, the chap who had the ex-Sayers Matador advertised here recently, had one of these as a living van and it was very nice, though a bit low if I remember right.

I'll give a chap a ring tonight about it - he might know someone for it.

If you want a build card, better get it now.

in American Vehicles

Posted

Yes, I know. The first article is from the local Detroit News today, building on the CEMA comment yesterday. The allpar.com item they reference is here, but it doesn't add much: http://www.allpar.com/news/2016/11/wpc-museum-closing-its-doors-for-good-34808

The second article was just for background, as there's a lot of information about what's at the museum for those who didn't know, like me. Obviously anything it says about the museum having re-opened predates the closure announcement and isn't relevant.