-

Posts

1,510 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by TooTallMike

-

-

Thanks for the kind comments. It's a truck type I've always wanted as they were very highly regarded both by the military and civilian users.

- MG

-

Sherman turret ring on the back?

:whistle:

-

So, here is my new project truck.

For those who do not recognise the type, it’s a wartime FWD SU COE GS truck. It is dated around 1944 and is a very original and pretty un-molested example. The front winch is not original and apparently is from a Cletrac. I do not intend to remove it as I like trucks with winches, it is very well installed and it doesn’t look too out of place.

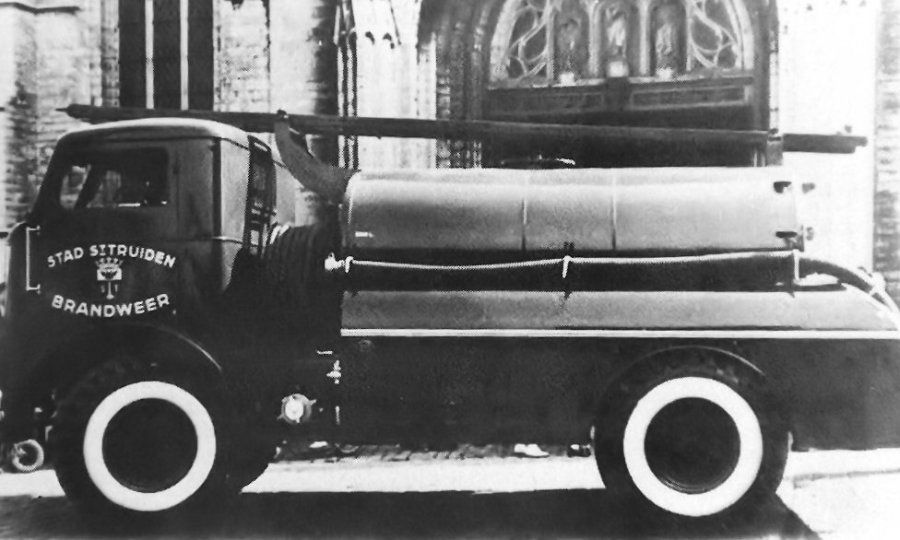

The truck is thought to have served on an airbase in Belgium prior to being acquired by the Fire Brigade (Brandweer) of the town of Sint Truiden. It is still partially sign-written in their colours and has a PTO and drop box installed under the middle, presumably to drive a pump. I found the photo below of another FWD in service with the same Fire Brigade and assume mine must have looked similar.

I say ‘another FWD’ as I do not think this is my truck: mine has only one layer of red paint over the military green and the sign-writing is very different to that shown in the photo. The green paint showing underneath does not look to have been rubbed down so if it was re-badged and re-lettered the old writing must have been very carefully removed first. Mine does however have two whitewall tyres on the rears! This all remains to be investigated further as I plan to contact the Fire Brigade to see if they have any more information and photos. The name ‘Trudo’ is written in script on the side of the cab and seems to be a nickname or abbreviation for the town name. This will be replicated after any re-paint. I have rubbed down some of the paint on the doors and sadly the original military markings do not seem to be there.

The interior is very original and appears to have been un-touched since its military days. The only additions are a pressure gauge with a copper pipe leading back to the back of the cab, perhaps relating to the pump, as well as direction indicators and a couple of extra switches for things like roof beacons and work lights.

Mechanically it seems to have been well maintained with everything greased up and moving freely. It still has the original Waukesha engine which now runs after I rebuilt the carb and flushed the fuel system. It would need new hoses and the rad needs a re-core but it’s basically sound. However I am also considering a diesel conversion to a 180hp charge air cooled Cummins B.

The plan is to repair the tiny amount of rot in the cab lower front corners, bash out the dents in the roof, remove the few extra welded brackets, repair the damaged LH wing, paint the cab exterior and chassis in drab green and fit a suitable body. A genuine body is not going to be an option and I’m not prepared to invest in building one. Ideally I’d like to find a decent Matador body as these are very similar but I doubt there are any out there not already spoken for. If anyone knows differently please let me know? Otherwise I’d settle for a cargo body from something like an M35 REO as it wouldn’t look too out-of-place. The body needs to be 2.4m(ish) wide and 4m(ish) long so any offers or other suggestions would be appreciated. Below is a photo of how it should look.

I need four new tyres for this truck and fancy a set of 14:00 x 20 XZLs so if anyone has a set for sale please let me know.

- MG

-

Confusion!

The Austin coupling in Tankograd is on my U-7144T. The coupling is to put it mildly a bit wierd, in that not only does it pivot laterally and longitudinally (like Dayton), but the cross-pivot pin is cranked - which means it can swing forward and back rising as it does so. This allows the coupling to rock forward and back to cushion movement between tractor and trailer. Quite why I have no idea - it seems to me it would make any trailer behave as if it had a load of liquid in an un-baffled tank, sloshing forward and back, sick-making!

The Austin coupling was attached by long bolts and clamp plates around chassis rails. The strange thing is that when I took it off to replace with a Dayton (stay with me here - as I need to lock out the sideways pivoting which can be done on the Dayton because the trailer has a built-in pivoting 5th wheel plate - doesn't life get complicated!), I found that the chassis had never been drilled for a Dayton plate.

The truck was reconditioned in Autocar's Ardmore plant in 1953, so I don't know if the Austin plate was a wartime pattern or a post-war type. And I've not seen another one. But it seems that - unless a new chassis was fitted - there must have been a wartime coupling with similar fastening method.

Couplings were supplied and fitted to the tractors at the trailer factory, not at the tractor factory. I have only seen Dayton pattern in any wartime pictures or manuals.

If you are not in a hurry I can try a Euro contact for a Dayton-type plate for you - it will be off an M series but other than not having DAYTON lettering they are identical, with the same characteristic cast baseplate.

Just to add to what Tony has said above - Tony spent several years looking for a genuine Dayton plate and it seems there are very few out there. If you can get an M-series one that looks right you'd probably be best off going down that route. Unfortunately having appeared in the Tankograd book, the Austin coupling has now edged its way into Autocar folklore despite almost certainly not being wartime, and quite possibly in fact being an early restorer's fitment.

- MG

-

This is almost certainly at Mike Panes' yard in Upton-on-Severn.

- MG

-

Thanks guys,

I wonder how I've not come across them before.

- MG

-

Subsequent to the tale Grasshopper mentions above, I established that a wrecker counts as a heavy locomotive since it is not designed or adapted to carry goods. A heavy locomotive is exempt test and can tow a laden trailer although that must be tested. Of course if your Mili is a cargo variant this doesn't help you unless you convert it to a ballast tractor. [Please note this is my interpretation of a very convoluted set of regs and should be verified by anyone following this course.]

You need to look at taxation class (since some exclude towing laden trailers), test status and driving license as all of these have a bearing. Insurance generally won't be a problem as most policies simply require you to be operating a roadworthy vehicle in a manner consistent with the Road Traffic act.

There are a few 'heated' threads already on HMVF on this sort of subject so it might be worth a bit of wading through the archives.

- MG

-

Thanks Richard,

So, effectively they're a double-ended shackle? I cannot think how many times I've needed one of those so unless someone really needs them to complete some CES they'll be going on the WLF!:tup::

- MG

-

If you want fatter tyres have a look at 9.00 x 20's as fitted to more modern M35 trucks.

Decent 11.00 x 18's are like hen's teeth and I'd advocate leaving them for owners of bolster trucks, DUKWs etc.

9.00 x 20s are cheap and plentiful and will give you the fatter rubber without spoiling the look. Plenty of photos on Google to give you an idea of what it'll look like. This will be my tyre of choice when I get another CCKW.

- MG

-

Hi folks,

I bought these the other day as they seemed too tasty to turn down. The problem is I have no idea what they are for. They're certainly bloody heavy. Does anyone have any ideas?

I've posted here as I think they are recovery items but maybe not...

If they are the thing you have been looking for since the dawn of time then let me know.

- MG

-

Could you please PM me Brian's contact details?

- MG

-

Do you require pre-booking or could I just turn up?

Oh, and will there be any 'farming' demonstrations?

- MG

-

Im not sure why anyone would do that.....I'm really confused, tap yes, punch !!!!!! he must have been on something surely.

Presumably because in Germany the driver's armour must be cut out and replaced with something that can be broken through so that any marauding driver can be more easily apprehended by the authorities. However I thought that usually it was replaced with thin steel sheet so even punching that would be pretty daft.

- MG

-

An extra non-return valve was fitted in the fuel system because this truck was suffering from fuel run-back and the lack of a priming lever meant it took forever to lift (this was when it was still 6V). I'm now adding two and two together and realising that was another symptom of the pump beginning to go bad (still drove ok at that point though).

I agree about thoroughly cleaning the tank out and giving it a good hoover. I'm still keen on the electronic pump as I've seen several 6-valve pump diaphragms reduced to canvas in parts over the last year, presumably due to the corrosive effects of modern fuel.

Points arcing may have been down to poor quality repro points? Certainly the 'original' Delco Remy set it now has fitted are considerably more substantial than the copper-coloured set that had got hot and been arcing. Could it even be that the Delco set being made of thicker material were simply able to absorb and then dissipate heat more easily?

Of course until the fuel pump has been changed and a successful road test completed it could still turn out that the problem remains and we were just lucky to get home ok.

- MG

-

I'm probably going to put the cat among the pigeons here but you did ask.

I don't primarily attend shows in order to show my vehicles off to members of the public. If any form of showing is done by the group I hang out with it is to each other and that's more about comparing work done, bouncing around ideas etc. I attend shows principally for the social side and we've often joked that the aim of the hobby is not vehicle preservation at all but drinking beer around a fire. All the rest is just leading up to that. To take W&PR as a good recent example, we were in almost the geographical centre of the site but yet probably only saw 250 public all week in our area (most of whom were lost and trying to get back to the other side of the site) but I'm not bothered as they are peripheral to my enjoyment.

I'm happy to go into an arena if we have some sort of silliness planned that will make it enjoyable, but just to go in so we can drive round in a circle and then park up for 5mins always seems a bit pointless. That said, we're off to the Lingfield Steam and Country Show tomorrow and they always make of point of asking if we can go into the arena so I'm sure I will.

I'm not sure what the conclusion is other than that show organisers could maybe look at other ways of letting the owners play and 'show off' such as having off-road courses, or convoys around the site or working areas rather than just the rather old-fashioned driving round a ring and parking up for 5mins.

- MG

ps. I have a fear of public speaking so any arena event where I'm likely to have a microphone stuffed in my face will be regarded with reluctance!

-

And the winner is...

Well, we took the truck for yet another test drive yesterday having put back on all the original ignition components and cleaned carb, lift pump and all fuel lines back to the tank. It still misbehaved but after a longer period of time than before. We then connected a gravity feed jerrycan from the passenger's seat to the carb and it ran perfectly. Very annoyingly we had already tried this weeks ago but at that time it didn't make any difference. I can only presume that we had an airlock or similar which gave the erroneous result and sent us off on the wrong track.

My conclusion is that the lift pump is at fault, even though there is nothing apparently wrong with it when it's in bits on the bench. It's the only item which is attached to the engine and therefore affected by the time/heat delay that we have seen. I believe any other faulty item in the fuel system would cause a problem on an erratic basis rather than consistently after a certain period from cold. Thoughts so far suggested are the pivot bush seizing or the spring losing its 'spring' when hot, also sticking non-return valves. It's an unusual model of lift pump for a GMC and doesn't have a lever which has made it all the more annoying to work with and diagnose.

Anyway I now plan to fit a low-pressure electronic pusher pump at the tank and do away with the mechanical unit. This will give three advantages:

1) positive pressure throughout the fuel system simplifying leak-finding

2) minimising the possibility of vapour lock

3) ethanol-proofing

Many many thanks to everyone who has given of their time and brains to solving this problem. It has been a very interesting intellectual exercise exploring the subject of ignition systems and I've learned a lot on the way, even if the final conclusion was in fact un-related.

Thanks again - MG

-

Chaps,

I spent a few more hours yesterday looking at the GMC again. I had already changed the LT wire from coil to distributor so it wasn't that.

John Comber very kindly offered the use of his running GMC as a donor for parts so I swapped out the entire distributor including LT wire, cap and 7x HT leads. This made no difference and in fact the truck began to misfire sooner than before (I doubt this has anything to do with the change though). As soon as it misfired I pulled over and checked the temperature of the coil and points and neither were more than lukewarm. I wedged my multimeter into the glove box and used it to monitor the LT feed to the coil (max. observed 14.2V) - there was no observable electrical misbehaviour during the periods of misfiring. I also monitored the coil to dist LT voltage (max. observed 11.2V) and again no disturbance when misfiring. Someone else suggested disconnecting the alternator to eliminate any possibility of over-charging. I did this but it made no difference.

I attempted to swap in the carb from the 'donor' truck but the tickover was very rough and it coughed and spluttered when attempting to pull away so I was forced to re-fit the old one. (Incidentally once home I refitted the carb to the donor truck and it immediately flooded so I need to take the top off and see if the needle valve has got stuck.)

At this point I decided to go for broke and drove the truck hard until it actually wouldn't go any further. Sod's law meant it stopped in a rather dangerous location but c'est la vie. I then carried out all of the normal checks such as spark at the points, spark from the king lead when the points are flicked, no overheated components, fuel coming out of lift pump etc etc and was unable to find anything wrong but it would not start. I took the top off the carb and it was pretty clean. After a while it was able to re-start and I was again able to limp the truck all the way home driving gently.

I then completely dismantled and blew out the carb. This morning I'm going to do the same for the lift pump and while that side of the engine is accessible I'll also check valve clearances.

And so the saga drags on...

- MG

-

@ Cosrec, the guys were doing what they could set up quickly in the time available and given the ground conditions they also probably wanted to avoid getting too much kit dirty on the ground for the sake of it. We all know that one of those Scammells could have winched the tank on its own but the public would probably rather see a line of trucks getting stuck anyway!

All this gives me an idea for next year's arena - what about using two trucks with winches to spin Shrek on its axis?

ps. sorry to all that we had to leave before the arena events but our house and stables were partially flooded out on Friday night and it was too much for the Mrs to deal with on her own.

- MG

-

As far as the 12v with ballasted system goes, the coil current will rise more rapidly at high revs than the non-ballasted system. So the magnetic saturation will be greater at higher these speeds so can give more output than the non-ballasted at these higher speeds. 90% saturation is all that is required for optimum output. Excessive current by increasing the voltage cannot increase magnetic saturation beyond the 100% saturation it was designed for, it will just produce more heat.

Clive,

Does this mean it could actually be worse with a ballasted coil?

- MG

-

I've never come across a positive earth system CCKW.

All wiring diagrams I've ever seen in the various TMs and later reference works (e.g. GMC CCKW by Becker & Dentzer) all show wiring diagrams for the various trucks dating from 1941 onwards with an earth lead on the negative post of the battery.

TM9-801 dated 1944 clearly shows a negative earth system, so I guess it is reasonable to assume that the mass of original and replacement CCKW components around are compatible with neg earth systems.

If this is correct, I wonder why this truck had been converted to positive earth?

Is this a clue in tracing the problem?

Thanks Tony,

This isn't the first +ve earth GMC I've come across so it looks like some were either built differently or were converted for some reason. Certainly this truck was +ve earth when I first got to it.

Purely out of interest the 1940 Maintenance Manual for an ACKWX, the immediate predecessor to the CCKW, shows that as +ve earth.

- MG

-

Mike;

On a 12 volt system, a ballast brings the voltage down to around 8.5 to 9 volts and its purpose is to prolong point life. You can use either an internally ballasted 12 volt coil or an external ballast. DO not use both in the same system. You can run a straight 12 volts to the distributor without a ballast however the point life will be shortened, by how much I do not know. Back in the day the standard was every 12 to 15 thousand miles you changed points, condenser, cap and rotor and plugs.

On a 6 volt system, you do not use a ballast as your are putting 6 volts to the points. They would each produce the same "power"

I hope this helps you out.

John G

Thanks John,

In our fleet we have numerous vehicles which run standard coils at 12V with no problems at all and no awareness of shortened points life. But then it's probably 5 years' motoring in a collector's vehicle to achieve the 12 to 15k miles you mention!

- MG

-

Mike,

I have been looking again at what you have done and come across this sentence above, where you say you have changed polarity from Positive Earth to Negative Earth. Am I correct so far? You say you have been getting your components from Rex, so the coil would assumedly be for an original +ve earth GMC? Coils are made to be on or the other. They do not perform correctly if reversed. You may be connecting it with switch wire to + and - to distributor, but if it a +ve earth coil then there could be the problem. You need to try a known Neg Earth 12 coil.

Maybe you have done this already and I missed it

Just occurred to me that the GMC was originally 6volt ........... you would not be using 6v coil instead of 12v? This will cause the points to get hot.

The coil I am using for all my tests was bought brand new from our local motor factors and is an Intermotor brand. I assume it is suitable for -ve earth since +ve earth would very much be a specialist application.

- MG

-

Comparing a 12v ballasted system with a 12v non-ballasted system, it is true that the voltage will be less at the ballasted coil but the current in both systems will be much the same, as will be the wear on the points.

The purpose of the ballasted system is to allow a boost to a cold start & increase the rate at which the primary can be magnetised at high revs.

Thanks Clive,

This is what I was hoping to see, and it suggests there should be no functional difference between fitting a standard coil and a ballasted one.

- MG

-

Thanks Clive,

I'm sorry for all the questions but I want to be sure I've got my head around this and I'm struggling to ask the right question.

What I'd like to establish is a theoretical comparison between the sparks achieved by a 'standard' 6V system, a 'standard' 12V system, and a 'ballasted' 12V system once the engine is running. Would there be any difference in spark from each of these or could they each be expected to produce effectively the same power?

- MG

FWD SU COE GS ‘Trudo’

in British Vehicles

Posted

In the absence of markings I am open to any suggestions. Tell me more?

- MG