-

Posts

1,510 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by TooTallMike

-

-

...I want to put new tires on it but the tires are foam filled, and the tires will have to be cut off. This will be VERY expensive to do. Like a grand.

Why would it cost that much? Surely the tyres can just be cut off with a 9" grinder?

- MG

-

Hi,

Those who say a seal cannot cause this are, with the greatest respect, wrong. We had exactly this problem with a new neoprene rear seal. We proved it on the bench and confirmed that was the cause. The starter would only turn the engine very slowly. We tow started the Jeep and drove it around and it freed up. It would then start fine on the starter. We didn't know about the potential for overheating the rear main but the vehicle has done many miles since the build, including at least one trip to France so I'm confident it's ok.

You need to be certain it's the seal though, and it's at your risk

.

.- MG

-

Hello Mike,

Yes I have an original gearbox, the bell-housing of the engine and gearbox is about an 1 1/2" difference.

I have made my adaptor plate now and all bolts together perfect.

I will start a thread soon about the plate and conversion.

Hi Jamie,

As Tony says, you just needed the correct diameter flywheel housing and it would have gone straight on. The Dart engine has an SAE3 whereas I think the HT is SAE2. I'll look forward to seeing your conversion in detail.

- MG

-

Hi Mike

Dug into the Ord 8-9 , I see the viscometer on page 139, looked at oil group 107 and the only thing I found is in group 107G page 70, COVER,oil filler and viscometer mounting, That is all I can find, No listing of a Unit Viscometer.

Also no listing of a viscometer in Ord 8 1952.

Looked at Tankograd no.1001 and 6029.

I also have SERVICE PARTS CATALOGE for HEAVY WRECKING TRUCK M-1 FOR KENWORTH 570 model, No listing of any viscometer.

I am thinking as you are, misprinted or was on a early truck,I am thinking ward lafrance series 1

Jeff

Jeff,

From memory I don't think there's even anywhere on the engine to fit one? On my Autocar (Hercules) it was mounted on the side of the sump.

Adrian B - the senders appear on Ebay quite frequently, but the gauges seem to be rare.

- MG

ps. just remembered that DT 980/981's have viscometers too.

-

I did one over Xmas and it came back in 5 working days.

I've got another that they are arguing over the dating letter but they are replying quite promptly even if not very helpfully.

I'd give them a couple of weeks before worrying!

- MG

-

Hi Jeff,

I just had a look at the ORD 8-9 and it shows that WLF Series 1-3 were fitted with 'GAUGE, oil level (dash unit)'; while WLF Series 4 & 5, and KW 572 & 573 were fitted with 'GAUGE, viscometer'. Further down there are various listings for 'GAUGE, oil pressure' so that is a distinct item.

The TMs illustrate an oil level gauge on the left-hand side of the dash in hard-cab trucks but I have not seen a Series 5 (M1A1) with a Viscometer. I'd suspect this is either an error, or that it was deleted from the production models after the manual had already been released?

Further to Longydagun's Mack's, the Autocars (7144 & 8144) were fitted with dash-mounted viscometers.

Regards - MG

-

This is all very interesting. I am currently working on putting a cummins 6BT in my M5 halftrack but I have taken a very different approach. The cummins engine I have came out of a bus which means it has a flat sump, the only thing I have had to get is a flywheel as buses run with torque converters. I have a Borg & Beck pressure plate and clutch which came out of the previous Ford cargo engine that my halftrack was fitted with when I bought it, and that fits directly on the cummins flywheel. I am now currently in the middle of machining an adaptor plate to fit the cummins engine to the original halftrack gearbox.

Hi Jamie,

We fitted a 6BT to an International HT something like 10 years ago. We were discussing it yesterday and we are sure the engine just bolted straight on. Has yours got a non-original gearbox?

- MG

-

Hi Richard,

I fitted one of these engines into a Diamond T Wrecker last year, which so far seems to be a success. I put the original DT gearbox on to it but had to change the clutch housing to the larger SAE 3 fitting which meant finding the larger flywheel, clutch, and starter motor. My question is, having retained the original SAE 2 clutch housing and gearbox, how did you adapt the gear change which I assume was remotely operated?

Tony.

Tony,

To avoid confusion, SAE 3 is smaller than SAE 2. You converted from SAE 3 to SAE 2

.

.- MG

-

Hi,

Last year I bought brand new 11.00 x 20's from our local tyre dealer. There was quite a choice from various manufacturers. I appreciate that wasn't in Iceland but the point is that they are available, as others have said.

- MG

-

I think the majority of post-military users had far more problems with chassis cracking and bending than any of the mechanical components. Even the military had trouble with the chassis on the 353 van trucks, hence the various field mods to add strengthening braces.

- MG

-

Just wondering if you have taken into consideration the increased torque the driveline will be getting. Tooltallmike has done several conversions on Ward LaFrance's with this engine, however, the driveline is heavier duty than the one on a GMC. I do not know if the transfer case and axles would take it as you are introducing a a couple of hundred more pounds of torque into the equation.

Your thoughts?

John G

John,

The engine spec I fit to WLFs are 125+hp more than this one, however there is still considerably more torque than the original truck design allowed for so I suspect it will have to be driven gently. I wonder what the weakest point of a GMC drivetrain? On a WLF it's the Xfer box.

Although it's not remotely the approach I would have taken, as an engineering project it's very interesting and I'm looking forward to the next instalment.:drive:.

Regards - MG

-

Just to be clear, the yard this gearbox is in is inhabited, among others, by a collector of Y types and NS's. He is well known in those circles. It is therefore no surprise that is what this is from, and he will be well aware of this since he owns several, albeit in bits.

- MG

-

Mk IV tanks definitly went to Russia supplied to the White Russian forces, and some were used post war in Germany during the riots of 1919. seeing where it is, it could also be assciated with buses. It was the date caught my eye.

Given where it is I would almost guarantee it's from a bus!

- MG

-

Hi all,

I am pleased to report that with the invaluable help of Singe and some known good components removed from his own vehicles we have managed to get the Dingo running a lot better. First a good carb was fitted so that we knew that side of things was ok. It still ran badly but maybe a little better. Six new spark plugs were then swapped in and the ignition timing was tweaked and it ran a lot better. We then re-fitted the old carb and it ran worse again. We shimmed the float needle valve out with another washer to further reduce the fuel level in the float chamber and the small seal on top of the emulsion tubes was replaced as it didn't seem to have been done in the rebuild. After that Singe drove it up and down the drive and declared that it wasn't too bad. It seems there is something wrong in the top of the carb but we cannot work out what as there's not a great deal there.

We think it would benefit from a replacement carb but they are rare and expensive. My gut feeling is that if it gives any problems in the future we should look at adapting a more modern carb onto it. (of course I'd be fitting a Cummins if I had my way :cool2:).

Anyway I have a set of plugs on their way and then hopefully it can be returned to its happy owner.

Many thanks to all on here who have given their thoughts, and special thanks to Singe and ChrisG for their loan of parts and their expertise.

Cheers - MG

-

Mike,

Only one washer used under the float needle valve, the edge of the valve has a lip making it look like two washers. To confirm, only one listed in the parts list.

I do not recall that arm being in overall kits for this carb. Just rebuilt one recently too. If it was not changed then this might have been the problem initially (before carb was rebuilt).

regards, Richard

Thanks Richard,

There are definitely two fibre washers there as I was surprised to see them, but as I said, with only one the arm will not physically go far enough up to fully close off the valve. Maybe this is the problem after all.

Sadly I'm away on business so cannot go and look at it but I'll investigate first thing on Saturday.

- MG

-

Mike,

That is a good indication that the float arm is bent out of true, allowing the float to rise too high.

regards, Richard

Richard,

That would make sense, and of course despite changing the float bowl, it would still have been the same arm. I believe it was changed as part of the rebuild but that doesn't mean it's set up correctly!

Looking at the rather poor quality drawings in the manual it seems to show two washers in this location but it is not very clear.

- MG

-

Sadly Roy has had 'flu for the last 3 days so the restoration wasn't completed on schedule. Normal service will resume shortly...

- MG

-

I'd recommend taking the opportunity to fit an alternator at the same time. Depending on the vehicle type there are suppliers out there that can supply alternators that looks like old style generators if the appearance is important. Otherwise there is a standard modern alternator out there for pretty much any application.

You will encounter a few people who will insist that vehicles ran fine on 6V when they were built, but how many new 6V cars are on the market nowadays? There's a reason for that...

You will not regret the conversion!

- MG

-

Mike

I replied to this, this morning but it appears to have vanished?

Should be able to come down to you on Saterday 10th if that helps, what dizzy do you have the round top or rectangular topped one? If in doubt post a photo.

will bring with me the following proven items

coil

plugs

complete dizzy ( square top type) with leads

dizzy round top with leads

new condensor

good MK2 carb

ive a 42 workshop manual that mentions over fueling at the carb and recommends to putting two card gaskets under the fuel pump to reduce the delivery rate. its an easy job to worth a try.

ive also had some problems with the spary jet delivering too mich fuel via the accelarator pump and flooding the middle two cylinders same as you. ( it is after all simply throwing neat petrol down the bore)

Make sure the accelerator is functioning properly and that the tiny brass/glass/steel ball and seat are in good clean condition.

found that differant thickness washers have been used under the needle valve brass seat. these range from 1-3.5mm in thickness. ive added aditional washers under some of my carb valves....this both lowers the float hieght and reduces the amount of fuel present. It appears to reduce the richness of the mixture slightly.

dingo carbs are a black art . Ive several, some of which also run dog rough for no apperant reason. ive had them completely appart and they do not appear to be any differant in setup to the good ones? interestingly swapping float bowls ( where most of the jets reside) makes no differance so theres something going on within the main body that ive not yet figured out

see you saterday/

singe

Thanks Singe,

Saturday will be fine for me thanks. I'll PM you my address and directions in the next couple of days.

Regarding the points you mention - there are two fibre washers under the float needle valve with a combined thickness of around 3mm. I tried removing one but then the valve doesn't fully close and it really does flood (everywhere!).

Thanks and regards - MG

-

Hi Mike, I have just read this and wonder whether the problem might be electrical. I had similar running problems with my Daimler armoured car which turned out to be plug leads which had broken down. The engine started and ran but wouldnt rev and had no power as it was only under load when the electrical integrity of the leads broke down. Similar symptoms occur with a dodgy condenser.

Sorry if I have picked up the wrong end of the stick but I never had such problems with Solex carbs in Dingos, Daimler AC or Champs.

Doug

Thanks Doug,

Once we've got a known good carb it will be a lot easier to track down the problem one way or another. I have heard these carbs are known for running rich and that they are known to foul up plugs 3 & 4, but like you, some people say they don't give any trouble at all! People's experiences may just be luck of the draw regarding the component quality.

- MG

-

Hi Mike,

Is your contact captain Crank? There was a post from him about his Autocar on this forum (he is a member) & I have included his post as the link in my post.

Sorry, I was in a rush and didn't click on the link. Yes, that's the one - I hadn't seen the thread either.

Whatever Cosrec says, the crane 'A' frame looks very similar, as does the vertical pivot. Even the large access hole on the angled plate on the right side is there on both. I agree the operating levers and gearboxes are not the same but the basic design seems to be.

Here's a photo of it when it was being delivered. It's the only one I have of the rear but if you zoom in you can see the similarities.

All the best with the truck. I toyed with buying it so I'll be interested to see what you unearth of its history.

Rgds - MG

-

Hi,

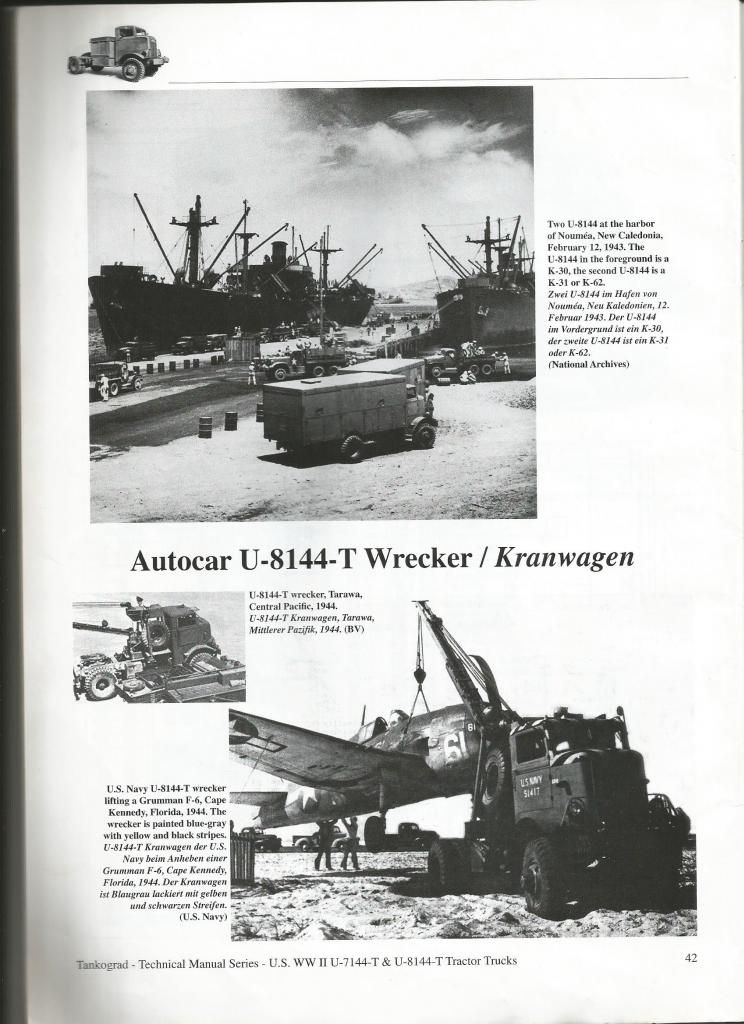

These are the only two photos I am aware of showing the Autocar US Navy crane and it can clearly be seen to be a GarWood similar to that of the WLF M1A1 so I'm afraid yours is not from one of those!

Page is scanned from Tankograd Autocar book.

More interestingly I have a contact in the US with an Autocar U7144-T fitted with a crane which is similar to yours. I won't post pics or details here without his permission but if you PM me I'd be happy to put you in touch with him.

Regards - MG

-

Thanks Richard.

Any idea what vehicle it was used on, and if its worth anything. They are nos and unopened apart from this one.

If they have been stored in a cool dry environment and without acid they should be good to use and certainly ought to have a value.

- MG

-

Sound very much like a progression jet issue to me Mike.

Hi Bernard,

I am hoping to take Singe up on his offer of a known good carb as we need to start eliminating components. I also hope to ask him to bring a set of plugs, leads and distributor cap so we can address that side of it too.

Rgds - MG

Electric fuel pump- what psi do I need?

in British Vehicles

Posted

I've put Facet solid state pumps on loads of vehicles, from Land Rovers to Ward laFrances and never used any form of external pressure regulation. You just need to be sure your needle valve is in good nick. If you size the pump correctly from the huge range available you won't need anything else. I agree the little filter that screws directly into the pump is inadequate - fit a good quality 1.5" diameter clear plastic one in-line before the pump and carry a few spares in the glove box.

1.5 to 2 psi should be fine but talk to Southern Carbs if you're unsure.

- MG