BenHawkins

-

Posts

861 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by BenHawkins

-

-

Another one! i will have to go and take a look in Smiths tomorrow. I expect Ben knows about it. Engine? Gearbox? Diff? what else was there? i am a bit worried when you say "near the sea". How near the sea?

I have seen photos of this one before. It is just a bare chassis which is extremely thin in a number of places. I believe it is actually a mid twenties 2.5 ton model on solid tyres (open propshaft not torque tube). The only part of the differential mechanism it has is one half shaft and the steering only has the track rod.

If however someone would want to take it on I have a complete back axle, gearbox and propshaft for this model. I can probably also make available a selector gate and brake/gear levers. I also have a radiator which could be used as a pattern, pedals and a bulkhead brackets and possibly some more bits if I ever make it to the back of the shed again!

However I think this particular chassis is beyond repair as is often the case with this model!

Ben

PS. Keep up the good work

-

Congratulations!

Fantastic job, I look forward to seeing it on the seafront at Brighton!

Ben

-

Thanks for sharing those great photos with us,

Ben

-

-

I had a vast range of quotes for it! The most expensive was 3500 pounds, but I paid less than 1/4 of that.

For my 30th birthday some friends purchased "a thread" each for me. I am very lucky that my friends are so generous as it makes the whole project possible.

Ben

-

-

I have been reading "The Automobile Engineer, July 1918" where they are reconditioning a Dennis Subsidy model. It states "Some considerable trouble had been experienced owing to breakages of the front springs....log book recorded renewal of the engine base chamber and front spring at the same time". This probably helps explain the lack of Dennis subsidy model sumps surviving, and suggests your issue may have always been a problem.

It also states that the spring camber was 3 1/2" unloaded and 2 3/4" under full load. The final word is that if a spring breaks the axle can move back to hit the sump, the usual clearance between these two parts being only 1 5/8"

It might just be worth double checking those dimensions!

Ben

-

Thanks,

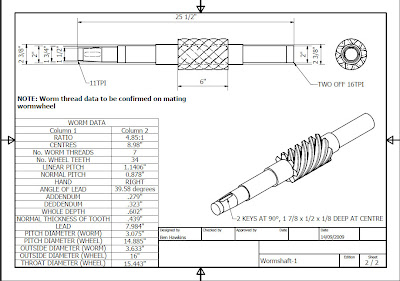

I am having the worm made at the moment (due in a couple of weeks). I will post a photo when it arrives.

Ben

-

It is great to see the progress and I look forward to borrowing the patterns for my water pump.

In the article on the Dennis subsidy lorry in the automobile enginner (September 1917) it talks about the drain hole in the pump casting being plugged by an "ignorant" driver resulting in water passing into the base chamber (sump).

I will take a photo of the pump gland spanner used by the RCS motor club. It is not an original Dennis one but it seems fairly effective.

Ben

-

-

The subsidy model had the smaller Benton and Stone (Enots) filter. This used the same head, but a smaller filter and bowl.

Ben

-

It is strange that the 'box joints that Steve has just referred too were used on fire engines but not on his subsidy lorry. Here are the essentials of a box joint

[ATTACH=CONFIG]22206[/ATTACH]

The bronze 'slippers' wear or in the worst case the actual box splits apart. Making sure that they are full of graphite grease before any journey ensures a longer life. Jezebel the RCS Dennis 'N' Type has had a fair share of box joint trouble but this probably because it is driven by students who have yet to hone their mechanical empathy. (Steve, didn't you use to drive Jezebel....?)

I used to drive "Jezebel" and box joints were never a problem if you regularly greased them (at least every 60 mile). This short service interval was probably the reason they were not used on the subsidy lorry. The original box joints (as listed in the parts book and drawings for my 1908 Dennis) did not have the bronze slippers and were just a square block in a square hole.

Ben

-

The earlier White and Poppe engines also used the smaller pump so perhaps there was something in the subsidy specification.

-

I have a Dennis drawing that shows grover washers under all fasteners on the silencer. The bolts on flanges also have holes for 16swg lockwire.

I may have a few spare Thackery washers as all my vehicles are meant to rattle.

Ben

-

When looking through parts books I was interested to find out that wooden wheels were also more expensive that steel ones (for example a Dennis steel rear wheel was £12, whilst a wood wheel was £13.10s).

One factor may have been the cost of repairs; if you break a steel wheel you need to replace the whole thing but a wheelwright could probably rectify a wood wheel.

That axle is interesting. It looks quite light weight (only single tyres?). It appears to be worm drive which Dennis patented however it does not look like any of their drawings which always appear to have had an inspection plate over the worm. Straker, Leyland and Thornycroft were to later use worm drive but this looks like a Napier to me (but that really is a bit of a guess and would like someone to prove me right or wrong).

Ben

-

I am very pleased to see the progress with the universal joints. Great job being done of them.

Ben

-

Really impressive progress. I hope to be able to make patterns like that one day. Such a lot of work is involved in each and every part.

Glad the drawings were of use, just a shame they didn't all survive.

Ben

-

I have the chassis, wheels, front axle, this complete rear axle, gearbox (missing a mounting lug), steering box/column (bent), bulkhead and brackets, later brake and gear levers to modify to the earlier pattern, and a later radiator that fits. I also have a flywheel and clutch but unfortunately only one engine between my two Dennis kits.

So yes a 1914 WD 2 ton would certainly be an option although there is also the possibility of getting the original registration for it as a grocers delivery lorry if the research pulls off. We will have to wait and see.

Ben

-

The fire engine axle is 4.85:1, but the original for the 1908 lorry was 7.1:1

Ben

-

Chris was very helpful with the bearings and delivery was speedy. I now need to put a dummy wormshaft in with the bearings to make certain I have measured the centre distance correctly and draw up the bearing arrangement to convince myself I have it right.

I have known about a spare back axle for a while, but didn't think the owner would ever sell. On Thursday I had an email, so I hired a van and visited the seller on Saturday coming away with this:

It is from a Dennis fire engine and although too fast for the 1908 3 ton it was an option for the 1914 2 ton.

The drive was all free and easy to rotate, and full of nice thick oil when I removed the inspection plate this evening.

No signs of bronze swarf, foreign object damage etc. so I am really very pleased with it. It will need a complete strip and rebuild but I am hopeful it will all be usable.

Ben

-

Similar dimensions to yours but a different ratio. Before I came across the wormwheel it was 3400 pounds for the pair

. I will update you when the price for just the worm comes in.

. I will update you when the price for just the worm comes in. -

Thanks Tim,

One of the other things I don't think I will find is the wormshaft. I have just sent this off for a quote but I think it will be expensive.

Unfortunately not something I can make myself.

-

The big challenge of early Dennis lorry restoration is sorting out a worm drive for the back axle. These have a ring of phosphor bronze weighing over 50lbs which was almost always scrapped even if the chassis, axles etc were found another use.

I have been fortunate enough to find a wormwheel, and my axle still had the differential cages, pinion gears and massive MS19-3/4 either side of the wormwheel. This leaves the wormshaft and it's bearings to find/manufacture/purchase.

One original parts books give the single row radial bearings as 16MS (or16m) and this ties in with the 5" housing. The double thrust bearings are given as 16MD (or16c) but I can't find a current equivalent. Any suggestions?

-

Tim,

Yes this is the one from Mick. The WD bought a few two tons and a number of three ton lorries the same as these although in no where near the volumes they bought the Subsidy lorries. My guess would be that there were problems obtaining sufficient parts for the subsidy lorries and they bought the older model as the parts were on the shelf.

The two and three ton are very similar vehicles, using the same back axle (available in different ratios), gearbox and engines. The three ton however had a heavier chassis (4.5" channel in place of 4"), was fitted with wider rear wheels and had a heavier weight front axle.

Ben

![IMG_8548[1].jpg](http://hmvforum.s3.amazonaws.com/monthly_2010_02/59dcb7bcb5fcf_IMG_85481.jpg.34b136da23a1e797de2c876df0c18ab2.jpg)

Solid Tyres.

in Pre WW2 vehicles

Posted

Richard,

Thanks for the information, I look forward to seeing this thread progress.

When I looked at the maths for elastic deformation of the tyre band it appeared that with the 3mm tolerance on the wheels meant that the tyre would most likely plastically deform when pressed onto the wheel (ie. it would be bigger if you pressed it off again). This means when remoulding tyres it is best to put them back on the wheel they were removed from.

Ben