-

Posts

7,704 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by ArtistsRifles

-

-

So much for EU wide compliance on everything..... Damned glad we can still drive Historic Vehicles over 3.5 ton unladen and not for hire/reward on a B licence prior to 1-1-1960

-

This is a good place for most things Range Rover in general and P38 in particular Tony:

Diag code readers aren't cheap though - this one is £355. Better off getting an independent specialist who has one to pull the codes for you.

-

We have a '98 P38. Nice motor but... It drains the battery every couple of days - something is waking up the BECM on a regular basis and that draws about 40A every time. Make sure all the electronics are working correctly. If you have to jump start it ALWAYS turn the lights on before connecting the leads, never connect the -ve lead direct to the battery, use a good earthing point on the vehicle. Ours is a 4.6 V8 so I sue the alternator top mount to clip the black lead to. If you don;t do this you risk spiking the BECM which is EXPENSIVE to rectify. Luckily there are a couple of places that can reprogram them but you are looking at an £800 bill. Do not ask how I know this.

Rot wise - check the wheel arches, door bottoms, lower tailgate and anywhere that can get stone chips. Check the steel cables that support the lower tail gate.

You say the HVAC panel is iffy - what do you mean there?

If you re worried about what might be hidden under the scene so to speak talk to your nearest independent LR specialist and have them hook their diag computer up and see what's revealed. There are a couple of good spares suppliers on eBay - good quality used parts - that I've used a few times. If you want I can give you the seller ID's. And you might want to consider joining the Range Rover Register - a good soure of technical knowledge and help.

-

Went to use the IMG tags on another forum tonight - and found that Photobucket have now disabled linking that way. The IMG code still shows to the right of the screen but you cannot select it any more. All you can now do is share in a FaceBook post or an e-mail - both of which just carry hyperlinks back to the photobucket page containing the image.

There was a survey link as to what i thought of their service up tonight so i took the chance to have a go politely about the way their greed had screwed up lots of valuable resources like these forums by them demanding we pay business rates to keep the 3rd party hosting and linking. I said a reasonable % increase on the existing plans would not have been argued with had they said they were incurring on-costs from these services but most who use it are NOT businesses and cannot afford $400 a year so are looking for alternate services. I ended by pointing out they could still make the change back as its not too late. Yet!!

-

On fuelling runs in the 70's I remember RTR units taking whatever we had on board - Derv, Combat gas, Kero, Avgas for the AAC helicopters. Nothing else. And sometimes a complete mix.... Can't say as to the engine adjustment's - you'd need either a Chieftain crewman or some one attached to an MBT LAD to do that.

-

I am almost sure the fitting is the same, takes a small glass lens inside and the larger lens on the outside.

Coincidentally I have a set on ebay atm with a base also shown, check it out to see if it is the same as yours. Item 201998173986.

The larger lens were retrofitted to most of the heavy vehicles and provide a far better light.

Weren't the larger upgrades the so-called "bug eye" type with the faceted lenses to improve the light dispersal and thus brightness??

Whereas the ones pictured in the original post are plain glass - kind of reminiscent of the Stolly ones.

-

You mean you missed this one for the bargain price of £7995

-

Nearly ready for a road test, then?

Very much so

All the lights now work.

Horn works

Brakes work

Handbrake works.

Only things that don't are the wipers- and I haven't tested them since the air pressure came up to full strength is the wipers.

Ideally I want these and the engine cut-off working before road testing. Oh - and I need to drop the spare and see what condition it's in - almost forgot that!!

Other than this - the doors just need to be re-assembled. Those new winders are causing me severe grief where they are cranked at the end as its hitting the cross bar on the door that carries the wiper mechanism. Need to either get them straightened or else get the arms switched over.

Everything else is cosmetic

-

Finally some good news to report!!

The braking system is now working 100%. Spent all Saturday fitting the new valve first making the classic mistake of bolting the thing onto the floor plates before connecting the unions. Stu's brother Neil was down for the day so got pressed into helping me with this. An hour later it was unbolted again and then rotated to get the Outlet adapters to be fitted and be tightened before being "wiggled" to allow their pipe unions to do up. With that done the Inlet did not line up but looking up I could see the holes in the floor and the bracket did not line up.

So - back up in the cab and a little leverage got all 3 bolts in. This more or less lined up the Inlet side of things - Neil got press-ganged again to help re-bolt the pedal back into place again and now the inlet lined up perfectly.. 5 or so hours work and another badly bruised left shoulder had the whole system re-assembled.

Started her up - and whilst the first leak source was sorted we had another. Pressure would rise to just over 60 psi then drop fast as soon as the engine revs dropped to idle. Wound up with all three of us tracing air lines trying to find the leak without luck.... Then Stu had a look up inside the chassis rails about halfway towards the back and found a little valve with an arrow on it - and in the best traditions of Army Engineering hit it with a hammer. Bingo!! No more leaks. Air pressure now builds to 120 psi as it should, holds there when the engine drops to idle and holds when switched off - took about 30 minutes to drop from 120 to 110 psi. We assume this is some sort of shuttle valve for the trailer brakes??

So that is one more job crossed off the list. Next one is the engine cut-off adjustment. Lift the pedal and it tries to kill the engine but doesn't quite meaning I have to resort to stalling her out. Not a good solution so next time I am over there its on the "To Do" list.

Next item on the shopping list is a socket to fit the wheel nuts and a 1m breaker bar. If I have to get under the front again I will have the road wheel off to save my back and shoulders

One thing I did notice when uncovering the cab to do the work was those taped seams on the roof. Even though the cab is covered with a 9x9 canvas the keep it dry they are bulging up and pressing on the bulges produces an horrible crunching noise. I am more than a bit worried about those now with winter coming on.

-

Ive just rejoined the 101" club after buying that truck.

I think there is a Ferret club to join somewhere

Now I also should also join the EMLRA

Next I should join the Series 3 club

Next I should join the LRCC

Is there a Sankey trailer club?

and if there is a domestic harmony club could someone sign me up for that one too?

R:angel:

Don't know about a club - but there is a Sankey group on FB

-

Cheers Pete :-)

I was just curious as to how much of a Jeep can now be sourced from the various specialists. From what you say it sounds like 99.9%.

Absolutely right on the hotness of discussing where restoration ends and new build begins - although I feel in this case it would be moot - if you build a Jeep completely from repro parts it is a new build - no existing chassis number as you say to give history and provenance. Wonder how DVLA would react?

"I want to register my 1944 Jeep"

"What the chassis number of the vehicle"

"It hasn't got one"

"When was it actually built"

"Last week..."

I suspect the conversation would go downhill from there.......

:)Now that blocks are being cast a huge stumbling block ( pun intended) has been removed however currently gearbox, transfer box and axle cases are still required as original units once these have been sourced everything else comes off the self in one form or another and can be ordered from your arm chair with the aid of your flexible friend.........but what you have is a kit car with no history or the remotest whiff of provenance :undecided: .

:)Now that blocks are being cast a huge stumbling block ( pun intended) has been removed however currently gearbox, transfer box and axle cases are still required as original units once these have been sourced everything else comes off the self in one form or another and can be ordered from your arm chair with the aid of your flexible friend.........but what you have is a kit car with no history or the remotest whiff of provenance :undecided: .It would take this thread way off course if we start discussing where restoration ends and new build begins, many a pint has been supped around camp fires at shows doing just that without any agreement ever having been reached as far as I know so if anyone feels bold enough to hold an opinion it's probably best done in a new thread.

But be warned it can become a hot topic :beatenup:

Pete

-

Just out of curiosity - could you build one from scratch without having the power train, frame and body at all? Basically by buying every part from a specialist supplier or sourcing from sales ads??

WOW! - £33,750 FOR A JEEP !!!it would be interesting to work out exactly how much a jeep would cost to build from scratch - as the advert for the auction stated that particular jeep was a complete restoration / re-build - so how much would it cost to visit the various jeep parts suppliers and do the same ? - would it really be £33,750...?

No it would be the thick end of £9K plus purchase price assuming you stared with the power train, frame and body in repairable condition and you do all the work yourself apart from the block machining and do not cost for time:

Engine machining and full rebuild

Gearbox and transfer case complete rebuild

Axles overhauled all bearings replaced

Rad recored

All seals replaced

Rewire

New tires

New canvas

Paint

Odds and sods

Pete

-

This article is worth a read - it highlights some of the options for replacing the Photobucket service:

https://www.ghacks.net/2017/07/02/photobucket-alternatives-for-third-party/

-

Very interesting - a bit of topic but worth discussing

Certainly on a UK regional basis (I was in a excellent position to witness) and probably nationally . Engineering training was annihilated at Technical Colleges by 1980 (certainly two different college machine shops I used were stripped out and equipped with stud-walls to train YTS how to emulsion , gloss and Artex. First year apprentice off-the-job full time training then the responsibility of local industry EITB workshops. I was born 1950 so was of the first year intake who had to do the similar EITB alongside Gity & Guilds craft . Of course the there had been (since 1950's) facility (G1 & G2 exams) to take the just sub-standard grades (failure at the 2nd part of 11+ , so to Secondary Modern , not Grammar School) . G1 & G2 - allowed entry to ONC (part-time) and OND (full-time, IIRC two extra subjects) - without the normally required 'O' level certificates. For apprentices , one full day at college and 2 or 3 evenings (doing "endorsement" subjects . Some would stay fully "in their trade" - a apprenticeship being 6 full years, others at 18 yrs. would convert to full time student on HND courses , often with a bolt-on as a "Junior Draughtsman" because you actually had to work during the holidays (other than the normal 2 weeks + Bank Hols.) . In the case of self - meaning another C&G T5 (Press Tool Design & Utilization) - that granted another "Full Technological Certificate". The system worked quite well - because you had the true 'technician status' within industry , when I had a problem on a 4-stage header tool for a National upset forger - I could at least talk to the Ch. Hand Die-sinker (that I had worked under for 6 months) on equal terms.

I was born in '56 - all through school I wanted to join the RAF as an airframe fitter, I sadly failed to get the CSE grades needed for that but unknown to me my parents had applied for a Ford Motor Company apprenticeship as a toolmaker. To keep them quiet I went for the interview and when asked why I wanted to work for Ford replied "I didn't - I wanted to join the RAF". Thinking that was that I headed home with a clean conscience - only to get the offer of acceptance a week later.... So much for honesty!

For better or worse I took the offer - a 4 year apprentice ship as a machine toolmaker following the C&G 255 Technician syllabus. Two years in the companies own trade schools - now long gone followed by two years worth of rotational assignments in different tool rooms on the Dagenham estate - also now gone. Once qualified I worked in the Old Tool Room in Dagenham MS&BD whilst continuing at first Technical College then Polytechnic. The 4 years of the apprenticeship and then the 4 years that followed that were spent attending these colleges on block release - 4 weeks at work, 2 weeks at college to get up to HNC level in mechanical engineering. You name the heavy machinery - I can use it -both vertical and horizontal forms of mill and grinder, lathes, shapers, planers etc as well as heat treat, welding/brazing and bench work. The latter being quite useful at times these days.

My daughter was born in 1990 and when we was going through senior school what we used to call the three separate subjects of TD, woodworking and metal work have been rolled into one - Design Technology. Having taken one look at what they were being taught from the class text books I gave her my old apprentice log books and text books. A few weeks later we got called in to see her teacher as he could not understand why she was that much more advanced than her class mates. Apparently the cruncher was when they were assigned to lathes with him expecting them to stand and wait for explanations - only for him to turn around and see her happily - and safely - turning up the work piece with a well constructed working drawing to refer to. The apprentice explanation answered a lot of his questions.

-

Got this back in response to my query as to why the album download function was not working. The more cynical amongst us may go "Ooooh - what a surprise - when they are facing losing hordes of subscribers this particular feature gets "broken""....

Hello,Thank you for emailing us. There is a known issue with the album download feature and our team is currently looking into it.

In the meantime, you can still download your images with the following steps:

- Step 1. Login to your Photobucket Account

- Step 2. Navigate to your library page

- Step 3. Click on a photo to enlarge it

- Step 4. Click the download button

- Step 5. The picture will be saved to your computer

Thank you for your patience at this time.

Best,

With album containing images number over two or three hundred this is not really a viable solution......

- Step 1. Login to your Photobucket Account

-

There is a "Download Album" function in the right hand menu block. But thus far I haven't got it to work properly.

-

The best laid plans of mice and men...... Getting over this weekend to refit the brake valves went out the window. - my own fault though, Sitting indoors of an evening staring at the brake pedal assembly it struck me how crappy it looked and how much easier it would be to strip and paint it here......

Started off by swapping the bolts around that join the body of the valve together so the three long ones are in the right place for the pedal to go back on in the right orientation. And refitting the blanking plug the supplier kindly returned to me.

First problem was getting the split pin out of the end of the cross-shaft. Suffice it to say I now need to replace the pin as the old one is in about 4 pieces

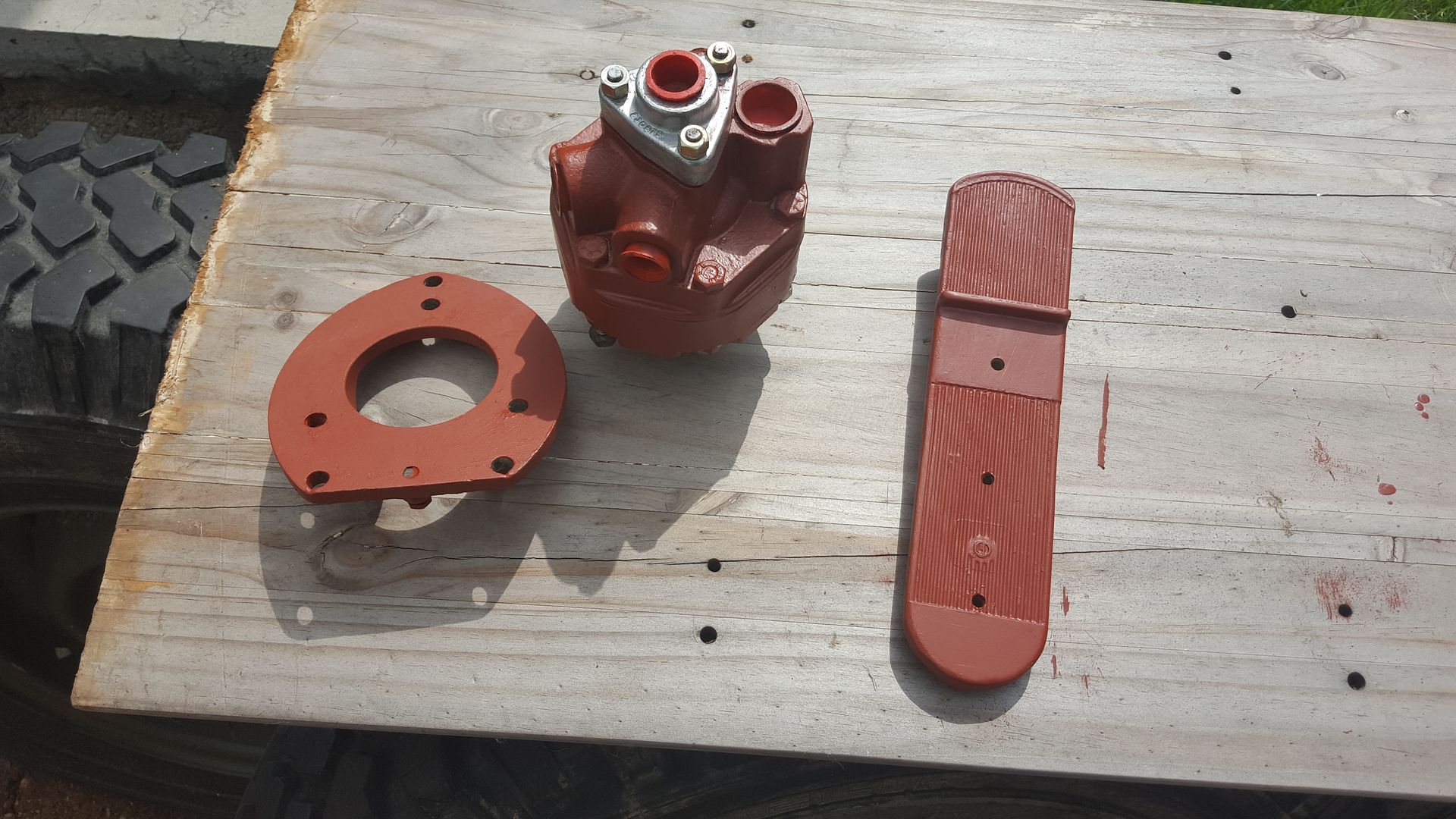

Once it was out and the crosspin driven out I started - three days worth of Nitromors treatments removed the thick layer of IRR green and the OE layer of Deep Bronze green leaving me with a nice clean pedal and base. These were then rubbed down by hand and coated with Bonda Primer. The new foot brake valve was also wiped over with thinners to get any residual grease etc off and given the same treatment:

Once that had dried for the time stipulated on the tin - 7 days IIRC - the first coat of Deep Bronze Green went on:

This was allowed to dry for the time stipulated - 16 hours then it was lightly rubbed down and the second coat applied:

The crosspin is back in place for now - but I think it might need to come out - it goes so far then stops dead so I am wondering if it is a tapered pin. Tomorrow I'll pop it out and try it the other way around.

Next weekend is Laycock at War so no work will be done then.

-

I really must learn to count! And I didn't know the 'aluminium' bit - they're certainly heavy enough! Thanks. Nic

Heh - try lifting a Militants steel wheels

-

And Stolly wheels are aluminium......

-

I feel its a bit unfair to say he does not care Rambo. As earlymb said - its a change in thinking required. Under Rex it was a show for us with the public as the add on. Now under the new guy the paying public are the be all, possibly the end all. He has experience in shows - running the shooting ones - so providing toilets should not be a new experience (showers probably are) and being charitable it is likely he placed a contract for X number of units. Being a business person the contract went to the lowest bidder. Hopefully lessons will be learnt and next year it will go to the lowest bidder with acceptable units.

Lets be honest - toilets have been a perennial problem at W&P since I can remember.

Lets be honest - toilets have been a perennial problem at W&P since I can remember.There are some good ideas on here as to how to alleviate some of the problems like concentrating into blocks as at Folkestone and having more disabled units. Maybe the ground conditions at Beltring - esp in Lower Monktons - lend themselves to more frequent emptying by smaller, lighter units? Or a self-powered trailer could be provided and a more suitable vehicle used to pull it around emptying the units?

What would be a positive step would I think be if either the new owner, or one of his people given authority to speak for him, was on here and a positive dialogue could be established. Rightly or wrongly the new guy has given the impression he doesn't care overly much about the MV owners and their needs/wants. Some else has said there is a "take it or leave it" atmosphere felt to be prevalent. If that is indeed incorrect dispelling it would go a long way to restoring the harmony between the guy running the show and those actually giving him a show to run.

-

Thoughts (personal only) inserted in red

I spoke at length to John today who is still quaking and trying to wind down after the show. He's still too busy so far to read any of the comments on here what with cleaning up and repairing the site.He is concerned about the issue of first comers roping of larger areas than they need and will have to find a way to police that. Go back to the old W&P scheme of having marshals for the various fields. It seems this year the America's was the worst one - get the Twickenham Offroaders back and involved - instant solution. Also move the plastic /public camping zone into the out-lying Medway field with a security officer on access patrol to keep the pikeys out.

However he's adamant that he provided well over the legal requirements of toilets and hired a local firm to supply them and empty and clean them on a daily basis. He's dumbfounded that a certain few should think that he instigated or was even aware that there would be no 'flap'!! To that end there is always the permanent toilet block with proper porcelain pans. However he's quite prepared to increase the portaloos by a substantial amount for next year. But is quite convinced that the complaints about toilets will persist like they have done since the show was first conceived. Probably spot on about the complaints persisting - seems to be a W&P "thing". The permanent blocks (there are two there) had queues all day. Unfortunately for him he IS the organizer and thus the focal point. Was I him - I would have a member of staff deputised to ensure that complaints and comparisons to the race course organization about showers and loos were noted on and acted on for next year. If nothing else he can then stand back and say "talk to him/her"

Oh yeah - and don't site a food van by a block of loo's - poor vendor at the main entrance kept losing crowds of customers when the septic truck arrived to pump them out.

My advice is " Take your own F*cking loo" like I do when I go to Normandy and any other rally. The £10 that some are whinging about will just about buy four coffees in most establishments. Umm - about 2.5 at the show this year I thought I saw the coffee stalls priced at £3.50?

On that note- at the race course the food vans in the Living History area were a bit cheaper than on the rest of the site - between 50p and £1. I do not know if that was an arranged deal with the vendor or we were just lucky in getting a cheaper vendor in LH? But it was certainly appreciated by those in the LH area.

Lastly - asking around the last few days - I get the feeling if he wants to attract the missing armour back he will need to repair/build bridges with owners who got more than a little pee'd at the description of them as basically scroungers and free-loaders for taking their families in for free in his first interview after buying the show. That, of course, is his choice

Ron

-

Its been a while sine the last update so here is the latest news on the UAZ... Readers may recall at the last time of posting the handbrake had just been reassembled, the old prop shaft refitted and everything tested OK and I was getting ready to do the doors. A little time then elapsed due to the wok on the Militant.

First lesson learnt - just because a door looks identical to the old one in profile etc. does not mean it is. I got the drivers side front door off and bolted the new one on. The reason for choosing this one was quite simple - it was the only complete door. The other three are a kit of parts with all the bolts and screws missing.

So - got the boor bottom on and the new catch bolt - and the damned door would not shut. I spent ages trying to work out why and finally, just before W&P the penny dropped. I pushed it, it swing in till about 12" open then bounced back again. Do rather than keep trying I stopped and looked at where the door was hitting. Turned out first it was because the new door has the rubber weather seals fitted - they were hitting the buffer on the A pillar. No amount of up/down or fare/aft adjusting would do it so I was forced to assume that the door hinges were sitting in too far. Adding approx 1.5mm worth of washers under the hinge plate alleviated the problem - not entirely but enough that the door would then shut and be operable on the outer door handle. Then I put the door top on - and almost back to square one. Door closes if slammed but the outer handle no longer works. And there are no rubber seals yet on the door top..... So I "think" I need maybe another 0.5mm to 1mm of packing under the hinge plates to get the door to line up and be operable.

The other "snag" I found is that the outer handle works by pushing on an "L" shaped plate - and the plate bends if pushed too hard so that the outer handle then no longer works. Maybe a fillet of metal glued in to reinforce it will help - I need to take a look at one of the "kit of parts" locks to see. Right now I leave the sliding panel unlocked so I can reach in and open the door on the inner handle - this has always worked well.

This took me up to the day before I was due t leave on the Saturday for W&P. Saturday morning I go to start it -and nothing. Spinning over but not firing. No problems think I - fuel has just run back from the carb so I popped the bonnet and started using the hand prime lever. 2 or 3 pumps later I am thinking "bloody hell my hand is cold" -when I looked the fuel line from pump to filter had split and the one from the filter to the carb was not far behind it!!

So bang (luckily not literally) went the trip to W&P that day. Frantic calling around and posting of forums and FB saw me headed down to Pirtek in Thurrock. They made me up a set of hoses in fuel resistant material that they said should last a couple of months as they had no fuel grade hose in. I now need to get the hoses off and back down to them to get the material replaced wit the proper fuel grade hose. Sunday saw me head off to W&P at last and it made the trip successfully. One problem occurred leaving home - there was a new sound as of sheet metal vibrating. Could not see anything major under the bonnet so I carried on and it faded away after a couple of miles. Finally found at least on of the reasons down at the show - the coil had lost a bolt and dropped off the top of the rocker cover down between #3 and #4 plugs.. So that got bolted back on Still a slight trace of the noise though and the tips of the fan blades are bright metal so I am thinking the maybe touching something. All they can be touching is the shroud on the radiator - and as that is solidly fixed I am wondering if the engine is moving under acceleration - as in the engine mounts are up the creek.

A problem that's been gradually growing worse is the lack of water integrity on the roof. At the show it reached the point whenever it rained it came straight through... Soaking everything in the load bed - which was bad enough but it also leaked on the big nylon tensioning straps that run between the windscreen and rear hood frame - thus soaking those and providing a lovely perfect path for the rain to run down and drip on me whilst driving. Never knew Russian vehicles came with built in shower!!

When I got home I broke out the remains of a can of Fabseal that I use on the Landrovers canvas - the UAZ hood is a plastic coated material so I expected the stuff to run off but thought I could work it in where the plastic might be thin. Climbed up the step, looked at the roof and it was a case of "what plastic coating" - entire back if the roof had lost the covering so when the sealer was applied it soaked it in. It wasn't till I got down below the door litop lie that I found the plastic cover restarting and the sealer running as I originally expected. The next rain storm should prove whether or not it has worked.

When I got home I broke out the remains of a can of Fabseal that I use on the Landrovers canvas - the UAZ hood is a plastic coated material so I expected the stuff to run off but thought I could work it in where the plastic might be thin. Climbed up the step, looked at the roof and it was a case of "what plastic coating" - entire back if the roof had lost the covering so when the sealer was applied it soaked it in. It wasn't till I got down below the door litop lie that I found the plastic cover restarting and the sealer running as I originally expected. The next rain storm should prove whether or not it has worked. -

Nothing I tried would free off that stuck cap - 2 weeks soaked in coke, freezing it or applying what limited heat I could. So I part exchanged it for a replacement unit from Erenetek. Brakes are not an area I want to take any sort of risk on.

New unit arrived just as I was leaving for W&P so it is still here. I am hoping to get over on Saturday and fit it. First though I have to get the blanking cap for the rear port back from the suppliers - I posted off the old one and then remembered I had not removed the blanking cap from it! Doh... Talk about a brain fade moment. My excuse is the UAZ was acting up again and I was focussed on that at the time!

One new D1 valve

One other thing I need to do is swap the long bolts around that go through the floor pan and secure the pedal in place as in its current layout the pedal is 180 deg out.

-

But surely Neil the type of vehicle you choose to own is up to you. Any hotel or campsite costs will remain about the same whether you turn up in a Dodge charger or a moped.

I didn't feel at all guilty at the first Armour and Embarkation when I saw Jim Clark putting "ANOTHER" £200 pounds worth of petrol in his Sherman and I'd run the whole weekend on £6 in my BSA M20. This is only a light hearted retort Neil but I haven't worked out the smiley on here!! Ron

And taken as such Ron

And I agree with greyhound32122

And I agree with greyhound32122  The choice of vehicle is ours as is the choice of whether to attend. I just made the point its not just a £25 week for the owners - there are other costs. Perhaps I should have said costs we pay happily, esp. now we are back at the hop Farm with that decent arena.

The choice of vehicle is ours as is the choice of whether to attend. I just made the point its not just a £25 week for the owners - there are other costs. Perhaps I should have said costs we pay happily, esp. now we are back at the hop Farm with that decent arena.On a serious note though, being in Living History (and being sites by the permanent loo's this year) meant I got to hear a lot of off-the cuff comments from passers-by and one of the main themes was the lack of heavy post/cold war armour compared to the last time the show was there. WW2 seemed well represented but the number of 43x's and CVR(T)'s was visibly down although Nick Vaughan's OT-90 was there, there was the Leopard a1 the restoration firm brought over but no sign of the Centurion, Chieftain's, T55, T62 or T74's that have attended in previous years. I think the Centurion AVRE was about it for that era. Perhaps the reason(s) why might be investigated by the organisers for next year and some way found of encouraging the owners to return?

Photobucket.......

in Tell us...!

Posted

Some? I suspect that actual number of lost accounts because of this will be significantly more than some - and that's without the unquantifiable damage done to the brand reputation!