-

Posts

133 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by FourFox

-

-

Yes Robin, one of the front ones is yours I believe. There were about 7 Fox engines going through my workshop at the time.

On the subject of unreliability of Fox engines...here is my theory:

One of the Foxes I purchased at the Jackson's sale had spectacular evidence of catastrophic engine failure. From the large quantity of debris (that had been saved in one of the flotation bins) and the remaining devastation, I conclude that the following series of events had occurred.

The engine had had a major seizure whilst the Fox was travelling at high speed. The momentum of the vehicle and the action of the gearbox, fluid flywheel and transmission (being effectively a direct geared system at this speed) had ripped the engine from its mountings and rotated the complete engine several times within the engine bay. The fluid flywheel had exploded into about 50 pieces, taking with it the bell-housing and rear gearbox flange, which suffered a similar fate.

There were pieces of the rear engine mounting,sump and fan gearbox in the debris, so I presume these were also involved!

On it excursion round the engine bay the engine had shredded both rear propshafts and all the oil cooler installation, meanwhile severely damaging the firewall and turret floor steelwork. Finally, having nearly ripped its way into the turret it mangled the rear of the commanders seat...which must have been quite a surprise for him!

One can only imagine the event from the crew's point of view. There would have been quite a sustained noise, followed by a large quantity of steam, oil, petrol and high speed hot debris, not to mention sparks from both mechanical abrasion and the severing of the starter feed cable!

I have pondered for some time about the cause of this event and have narrowed my mind to some possible reasons.

1. The engine just threw a rod, which jammed the engine solid instantly...not very likely..I have many engines with thrown rods and they just tend to break the sump (not even that sometimes) and make a lot of noise!

2. A snapped crankshaft allowing the fluid flywheel to explode, taking the bell housing, disconnecting the engine from the gearbox and front engine mountings...again not very likely, as the input shaft to the gearbox was not damaged (and indeed was re-used in the subsequent restoration).

3. A driver's mistake...changing into a much lower gear whist travelling at high speed. This is easily done on a pre-selector gearbox (the Scorpion's sequential change makes this much more difficult, he can only really do one gear at a time) (also on a car type manual, or automatic gearbox it's not easy). I would have thought this action would have disintegrated the gearbox before achieving sufficient engine revs for an explosion! The jaguar racing boys can get an incredible speed out of these engines (when properly balanced).

What do you think?

Perhaps this explains why the Fox engine was not as reliable as a similar Scorpion one!

Why doesen't this happen on Ferret (or even Dingo, Saladin etc.)?

Fox gearbox with most of the damage removed.

Gearbox rebuilt (in situ)

Jon

-

The 'slotted' block refers to 5 slots being machined in the top face, one between each cylinder. This was done to prevent cracks appearing between the cylinders at this position.

The early military use of this engine highlighted a serious cooling problem, presumably because of the engines relying entirely on fan cooling (not assisted by natural forward motion wind through the radiator, as in the cars).

From experience of testing the limits of many engines, it's usually the oil temperature that sets the limit of how high an ambient temperature can be tollerated. This may also have been a factor as the sump and any oil coolers are not cooled by vast amounts of air passing them.

The early blocks also has their coolant holes to the head enlarged and additional 'block to head water holed' drilled (we always use the term 'coolant'. not water, to avoid confusion) in an attempt to improve cooling. Hence the 2 types of head gasket.

Here is a quote from my EMER 2300-E-200-533

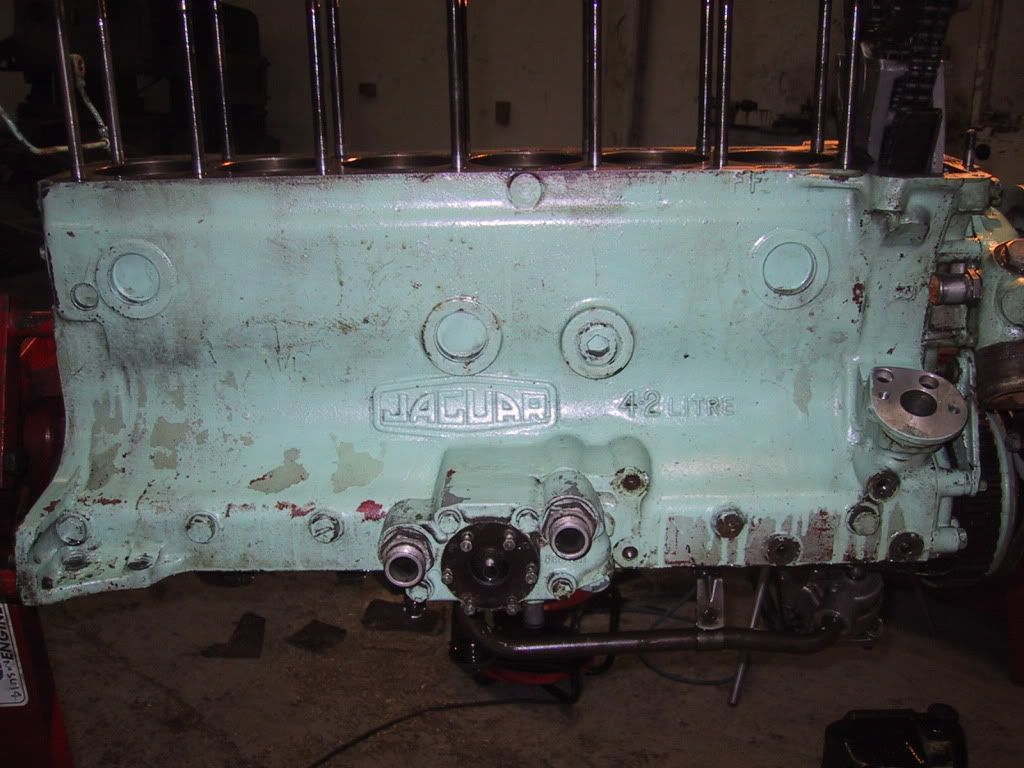

' Two types of cylinder block in use. Mk 100 engines-linered, combined blocks with full length dry liners and crankcase.

Mk 101 engines - slotted, combined block with siamesed bores for cylinders, additional block to head water transfer holes and water slots instead of water ports between cyliders. Integral crankcase.

Mk 100 engines converted to Mk 101 at overhaul by incorporation of non-linered cylinder blocks are to have original engine number suffixed by /1.'

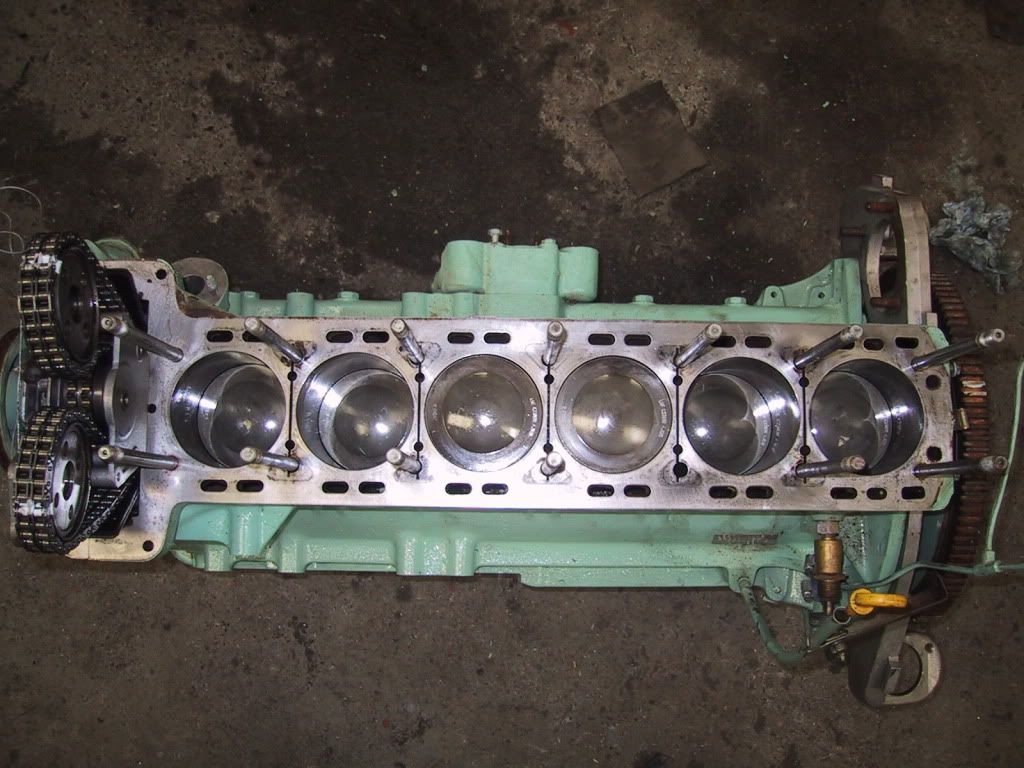

Here is an early prototpe Fox engine..no liners, no slots, no ribs.

Here is an early Mk100B Scorpion engine, liners, no slots, ribbed block

Here is a later Mk 101B Scorpion engine, no liners, slots, ribbed block

Early blocks are quite different, and easy to recognise. No ribs

And here is a later Mk101B..with ribs

Now have we all got that? Or do I have to go into more detail?

Sorry about that, I do have a thing about these engines.

All Mk101B

And the final test..3 Mk101A and the prototype Mk100A..spot the difference!

Jon

-

Thanks Nick for the photo. It's great to see pics of ones vehicle 'in service', even if it is only during testing and development...an essential part of the manufacturing, as there would be no further Foxes without the successful completion of this stage!

It sure looks like my prototype Fox. It still has the old Ferret/Saladin type headlamps fitted. This is the only prototype that I have records of being fitted with this type of headlight. It has been later fitted with an additional pair of 5 inch Butler units, presumably to improve the night vision at speed...in the woods!

I notice that there are substantial ballast weights fitted both to the hull and turret sides....the holes are still in the hull sides. Later pictures show much thinner weights fitted to the hull sides and glacis plate. By now the correct shaped turret has appeared. (This may account for Robin's 'rear down' observation)

Incidently, the turret of the prototype has a much different construction to the later production ones.

The 15 prototypes (I think) were the last armoured vehicles to be made by Daimler...who ceased making 'armoured cars' after losing the Fox contract to ROF Leeds. I have heard that Alvis continued to make the turrets (all of them?).

From my observations whilst driving other Foxes, the suspension hardly moves at all when on the road, the ballon tyres taking up the minor road shocks. The first round-about is a bit of an 'experience'. The independant, double wishbone, coil spring suspension is very effective over the (old) jumps at Beltring.

That reminds me..I must check the gearing of the prototype. Mechanically, it appears to be the same as a Mk4 Ferret. The early E-type engine it was fitted with is capable of at least 5,500 rpm and well over 200 hp! No wonder all who have driven it says it is very quick!

I have re-built a propper Prototype Fox engine which will be perfect for this restoration. It is quite different to later 4.2 Jaguars and appears to be a 1968 military modification of an E-Type engine with the famillar military Solex carburettor.

The head, block, sump, con-rods, camshafts, exhaust valves...even the camshaft covers and breather are all different to the later engines. To make life even more complicated, the bell-housing, front tomb-stone and the entire fan unit is also different.

The Fox at present has no power steering fitted. It appears to have a Ferret, all mechanical, system. There are the remains of an earlier power steering installation...again quite different to later Foxes. I will try it out with what it now has, but have all the bits for a later power-steering conversion later on.

Keep you posted on progress.

Jon

-

It could be that this box is for temperature recording apparatus!

There are over 20 temperature probes around the engine, cooling and oil system of this Fox, even some on the alternator control box! There is also the remains of quite a lot of surplus wiring (which was presumably used to couple to the temperature probes).

I have used a similar method whilst testing my new designs for electrical power generator canopies. The recorder box nowadays (called Squirrel) is only about half the size of a shoe box, and is powered by a small 9v battery!

We have to run the set at rated load until all the temperatures stabalise (for at least 1 hour). If the (mainly oil and coolant) temperatures are within the prescribed range for the engine and alternator we can then calculate the allowable maximum ambient temperature for running the generator....simple really!

There are also several pressure gauges on the inside of the hull..now sadly disconnected.

Anybody out there have information about this testing of the Fox prototype?

Jon

-

My restoration of the prototype Fox is now proceeding and painting is due to start as soon as the weather improves.

All 4 bevel boxes and 8 tracta joints have been reconditioned with (mostly) new parts from my stores as they were in a poor condition due to lack of lubrication.

Whilst I was at it, I have renewed all the rubber dust-boots (they were all rotted away), handbrake bands, disc pads, track rods and most oil seals.

Quite a few parts are different to production Fox parts (I am assuming they are related to Mk4 Ferret bits), but I have managed to source all the correct components. I am now getting quite good at taking apart stuck tracta assemblies and assembling the new 'Chinese Puzzle' of the tracta joints, swivels and bevel boxes.

For some reason the 4 propshafts appear to be NOS, but without their grease nipples! I have now serviced them and put in nice new greasers.

I have has the lids off the gearboxes (they appear to also be Mk4 ferret) and adjusted the bands (plenty of meat still).

There are still a few oil drips to sort out before the engine is installed.

I hope to add more restoration pics. during the next few weeks.

Meanwhile I notice from one of the archive pictures of my prototype at MVEE there is an insignia on the rear turret box.

Has anyone out there got a colour picture of the MVEE insignia that I may copy, to make up some stickers for the front and rear of this Fox (and also my prototype Scorpion)?

Incidently, does anyone know what the turret box was for? It appears to be the right size for a couple of standard Nato batteries (for the radio) but there are no suitable holes in the turret for the battery leads.

I have a picture of one of the prototypes with ZB298 battlefield radar mounted on the turret, so it could be related to this!

None of the other prototypes appear to have this rear box type mounting.

Jon

-

Actually, you are right! It's never happened to me in the arena, it's only Brian that gets mad enough at my reversing to resort to 'mirror bending'.

-

The basic commands for manoevering in the arena at Beltring a relatively straightforward, although I wish they would re-set the wing-mirrors afterwards!

I was confused by the marshal signalling to me by patting himself on the head!

Upon asking what this was for? he replied 'take your directions from me'...obvious really!

-

I can give you a clue..

Here is a photo taken during the filming.

I have seen the vehicle...love the cammo net over the ratchet straps!

-

Must have been the shortest CVRT built.

My Scorpion was built to have 80 links per side (Non turreted variants had even more).

In practice I managed to remove 2 links of new track during fitting, but it is still very tight without much pressure in the tensionners.

I make that 78 links per side!

-

Thats the same as mine!

I bought it of a stall at Malvern in the spring. It was £45... a bit steep, but cheaper than making up a spoof battery pack!

You can remove most of the battery holder from the assembly and wire it up as suggested...works fine.

Jon

-

My A41 has the serial number 2171.

Does anybody know when this was built?

It runs fine on a French made inverter which sits in the battery box.

I need a headset...anyone got a spare?

And what is a complete set worth?

I have a spare aerial.

Jon

-

Hi Andy

Here are some pics and info of my Larkspur A41. I presume this is what you are seeking?

I stripped the radio and its canvas accessories and photo'd just the frame. It took about 10 mins.

Frame has a Nato number 5999 99 949 7565. It comes with the shoulder straps attatched.

It looks quite difficult to make. I can give you some dimensions if you require.

Here is the A41 radio in it carry bag!

You will need a radio bag 5820 99 949 7565

And 2 accessory bags 8105 99 102 7949

And one spare battery bag 8105 99 102 7948

And one aerial bag 5820 99 105 2727 Its the long thin one on the right of this picture

I then put it all back togrther for the final picture. It took over 40 mins as I had forgotten where all the straps and buckles went!

Finally here is my A13 HFset. Does anyone have a spare RF amplifier for this so that I can fix the aerial?

Regards

Jon

-

Did anybody mention Saladins in Sri Lanka?

Sounds like the cue for a song!

Love the driver's cap plume!

Note the interesing aerial bases.

Even more interesting device fitted behind where the horn used to be,... an air horn?

And what's that mushroom shaped thing under the swivel mount?

Jon

-

The 30 Cal pintle mount for a Saladin is almost the same as the wartime mounts for the Stuart tank and many other vehicles. I differs in the magazine mount is at a greater angle in order to miss the periscope guard.

If you find a similar one, I have a spare NOS magazine mounting box that will enable you to make the correct conversion. I also have the correct NOS mounting pin for the 30 Cal.

Jon

-

The Challenger One has the registration 94 KC 37 and served with the Scots Dragoon Guards in the First Gulf war.

Their museum (still in Edinburgh) has contacted the new owner and requested to be kept informed of the restoration progress. Meanwhile its full history with dates and relevant personnel, is being reasearched by them! More info to follow when this arrives.

-

Good luck with the welding! Mine is getting quite good now having recently done over 2,500 welds on 1.5 amd 2mm thick box section. It's just practice...lots of practice.

You should be at this stage in about a week!

Regards

Jon

PS do you still want the smoke dischargers?

-

Mark

The Scorpion should be on it's way to The Dunchurch AFV show on the Bank holiday weekend.

Someone is bound to offer me the asking price of £25,000....so I don't have to pay the transport back to Sandwich.

It's a good show to visit. It's a great venue and has the best simulated live firing of the 76mm guns. See the pictures of last years show on the AFV website.

Jon

-

-

In a similar soloution, I have one of those portable battery/starter booster thingies which has 3 twelve volt auxilliary cigarette lighter outputs for phone charging etc. Works a treat. It lasts for weeks, and you can re-charge it from any mains outlet or 12v source.

Jon

-

Possibly...This is a very early Fox and has not had many of the modifications that are common on all other Foxes I have seen. The rear bins are the early type without external doors. The driver's hatch release has not been modified for internal release mechanism. There are no holes in the hull where the decontamination brackets would have been. The exhaust pipe outside the hull is the solid earlier type.

The paint colour still remains a mystery...on further scraping yesterday it appears that the hull was originally the standard NATO green all over from the factory. Then it was painted all over in black and the stone colured patches were applied on top of the black!

If the stone colour has faded from green it must have been a chemical reaction, as even the drips down the back of the floatation bins have turned the same colour!

Jon

-

Could have been faulty paint...but I doubt it. Even where the sun don't shine it's the same, even underneath the black.

The only green on the outside is vegetable...mould or moss!

All the other Foxes I have restored have had quite good Nato green finish both on the surface and for many coats underneath. This one looks like only one or two coats have ever been applied to the hull. There is also so little paint on the mud-wings that they are rotting away. Fortunately I have a spare set of tinwork for this one!

Regards

Jon

-

Hi Mark

Have a better look at the Fox in the cormer of my workshop!

It is still in the original colours when cast from the MOD in 1989 or 1990.

It is sand and black. The sand colour is more 'stone' than the new desert yellow.

I shall eventually get around to repainting it in these colours...and then we shall have 2 on the circuit that are not the usual green.

The protoype Fox is due to be restored to its original DBG.

Incidently... the protoype Fox at Bovingdon is in Berlin brigade urban camoflage block pattern...which it almost certainly never was in service.

There is another Fox in the AFV shed at Rugby that did serve in Germany and has the remains of the original Berlin brigade decal. This one is the usual green and black.

Regards

Jon

-

Hi Matt,

Jaguar E Type engines are quite a lot different to the later XJ6 ones.

I have one of the first J60s converted from an E type civillian engine to military spec in 1968.

It was fitted to a prototype Fox (and later this year will be fitted back into a prototype Fox).

Apart from the obvious external differences, such as carbs, manifolds, starter, distributor, engine mountings, flywheel, crankshaft damper, etc. there are also internal differences.

The camshafts are 2-bolt fixing to the drive sprockets and have an external end thrust restrictor.

The exhaust valves have a thinner stem and the cam followers (tappet) are smaller, being interchangeable with the inlet ones.

The connecting rods are a different pattern having a different shaped strengthenning web and are polished on the side faces to resist cracking. they have a castelleted nut big-end bolt fixing.

The block casting is quite different and has a much smoother line with fewer core plugs.

The rocker covers are smooth and not ribbed. They were polished to a shiny finish.

The sump is a different shape and has side ribbing fo extra cooling.

All the oil pressure relief block and the filtration system is different on the civillian engines.

Having mentioned some of the differences, most of these changes were made after military trials of the civillian engine showed up several shortcomings, mainly on the cooling. These changes were then incorporated in the production for the car engines. Most Jaguar racing enthusiasts use modified later (or civillian) engines as they are more reliable (and cool better).

So the conversion to a £2,000 E-Type engine would be quit a job! Also it would be quite expensive...The ribbed sumps are hard to find (E Type owners keep breaking them on speed bumps). The smooth rocker covers are also a treasured item.

Regards

Jon

-

Hi Matt

My latest thinking on paper gaskets for the fluid flywheel is to use a sealant (intead of the paper). It has to be resilient to high temperature, as you know things down there can get pretty hot!

I use Blue Hylomar. You have to get the mating surfaces free of all paint/debris etc. before applying. Use plenty.

I also use sealant on the bearing centre carrier and flywheel bolts as these can be a source of leaks.

Leave the sealant to set for 1 hour.

Fill the flywheel with fluid up to the filler plug being careful not to spill any (it helps when checking for leaks).

Check for oil leaking from the joint and center oil seal.

Turn the flywheel to a few positions and leave for a few hours to check for leaks again.

If any leaks, then it all has to be done again.

You can adapt a filler plug to enable the flywheel assembly to be put under about 15psi to test for leaks.

Then bash over the tab washers.

I think that the reason for Ferret (and Saracen/Saladin) having a paper seal and the Fox doesn't is that the J60 is capable of running much faster (5,500 rpm and more before it all goes bang!). The higher centifugal force possible can dislodge the gasket or force the thin oil past it, causing a leak.

Once the Hylomar has sealed, it doesn't appear to fail.

I have now done 8 Fox and 2 Saladin flywheel repacements.

I have had to re-do the hylomar seal 3 times after finding small static leaks.

I now do it properly and use more goop!

Regards

Jon

J60 Jaguar 4.2l engine variations

in I may be stupid, but......

Posted

Sorry, I didn't take any pics of the 'before' situation. I probably have some of the bits left. I will have a look in my scrap pile.

The Fox was sold some time ago to Graham in the NE. I believe it was still going ok when recently put up for sale!

Jon