-

Posts

96 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by CornishMade

-

-

10 hours ago, Minesweeper said:

Thank you so much for yours and your dad's in put into this, Emma. Amazingly, it was more than 30 years ago that I bought the Peerless and the poor thing has been waiting in the queue to be worked on all this time - we have done four other lorries in the mean time so we have not wasted our time! During that period, we have acquired a lot of information about Peerless and also a lot of pictures of them, but strangely enough despite the large numbers of Peerless' that the WD had and that were later sold off after the war into a civilian life, very few of them and bits of them have survived when compared with other makes. We have enough bits to do a second Peerless - but not an engine for it. There must be one somewhere!

Anyhow, from all of the pictures we have carefully studied, we are convinced that with the majority of Peerless' that left the factory when new, the Dashboards were of wooden construction with the outside parts consisting of vertical planks but in the centre section, the planks were laid horizontaly. So that is how our good friend Mark who is a very skilled woodworker has made ours - in Sapele - and a beautiful job it is. It will be a great shame to paint it! We think that it will probably take another year to finish it all off.

Having done other American built trucks previously, we were convinced that all of the threads used in the Peerless would be either UNF or UNC and initially struggled with that as nothing seemed to fit as we had not identified the problem. Another reader of this thread some time ago after we really got started into it, suggested that the threads could be UNS which rather puzzled us - but he was absolutely right and that is what they are - we had not come across that one previously. Another reader of this thread sent us a photograph of a box of taps and dies that he had bought at an American Autojumble - and the box was labeled - "Taps and Dies for Peerless". They were UNS. I should be interested to know how your dad got on with this - you cannot buy UNS nuts and bolts and we have made our replacements as we have progressed!

Tony

Tony before I forget dad also mentioned he was sure he saw an advert at some point in his travels that peerless could come with an 'L' series gardner engine....didnt say were or when and I'm not sure if the advert would be among his photos or papers..he seemed to think you would understand....👍

-

😆🤣🤣🤣 dad may be wrong as it may well have been 1984 and 1986 it was while I was at secondary school and that was 1982 until 1987, and I used the photos in my English language exams( o' levels and cse🤭) so may well have been, it may have felt faster as wooden wheels and everything vibrating and rattling..including our teeth, we followed up in the car and the lorries went by low loader rather windy may bank holiday weekend👍👍

-

-

Morning, I'm down with dad at the moment, read out all the comments,

Yes dad said he had similar issues when it came to nuts and bolts he found some Leyland valves cut the threads off and made them to fit, and Albion reiver donated bushes for the back end, and apparently a local bookmaker supplied the leather for the clutch, an engineering firm did the front springs and he says the copper pipe from carb to the petrol tank was 3/8"

Originally a sand tip was moved ie they reduced the size down and took away the sand and the lorry was discovered underneath,It was used by parkin and Peter's a clay company for transport, rumour has it they had 2, one number plate..while one was being loaded the other was delivering and once back they would swap the plate and drive the full one out and start loading the empty one 🤭. my dad's dad (my grandad) actually got it put in the clay museum but he passed away before he could restore anything. Father then took over about 1978 and went from there, we did local rallies with it driving it there usually, and in 1982 and 1984 dad did the London to Brighton in it and finished twice, first time only casualty was the tank for the carbide lamps came off, second time no issues and the Dennis fire engine in our class said we clocked 22miles per hour down hill on the straight....bit of vibration there, we continued to rally it locally until about 1997/98 then dad started having issues and needed bypass surgery...wasnt able to do much after that and it still up in the wheal martyn china clay museum I can put the pics up later 👍👍

-

4

4

-

-

-

Evening folks, I had a good chat with dad today, he was impressed with the dashboard oil gauge you're making up, he said he had to fabricate a bottom piece for his and when it came to the glass tubes...somebody knew someone and they turned up, his suspicions they came from ecc labs but who knows...the next... the cab, he said he made a 'firewall ' of planks attached to a sheet of chipboard/something similar and all bolted together , not that thick , but we had a cab and windows, going by the pics a lot of the peerless trucks featured, have no cab or glass windows, like the sandstone one, and it could be the new owners of war surplus made them suitable for their own specific needs, I'm sure dad saw an old photo of a group of them bought for a haulier I think they were called Vincents local to us so that's probably why ours looks as it does, there may not be a right or wrong style other than the military version and they all seem subtlety different...👍 if that's any help.....

-

2

2

-

-

-

2 hours ago, Minesweeper said:

Thank you Emma! I am glad that your Dad is following our progress - I am sure that it will have brought back a lot of memories to him from when he did his. It has been quite a long job and I am sure that your Dad will nod his head in agreement when I say that no job is ever straight forward and that you will always find things that you were not expecting that you have to do! The Goslings send him - and you - our kindest regards and best wishes.

Thankyou, I will I'm seeing him again Thursday, so will take him through the oil gauge your making up, I think the one dad had came from America..

-

On 8/6/2023 at 5:32 PM, Asciidv said:

Even though they might of had plywood back in the day, I still think using it would be a bit of a cheat no matter how well executed it was done.

Hi folks, I cant remember what dad used but the pics are a past and present of the one he did, it was planks I think, we have been still watching although not logged in and I've been reading to dad how you have been going, his eyesight isn't so good and hes been in hospital twice since may, currently hes still in so I'm still reading out what you get up to, your doing a brilliant job👍👍💓

-

1

1

-

-

On 9/15/2021 at 8:13 PM, Old Bill said:

.ooh know that feeling

-

We have been watching this post with a great deal of interest, and I have been updating dad with it as far as possible with the isolation rules applied, out of interest if you can get the Smithsonian channel, America in colour, the episode with Ford, firestone and Edison has a great deal on ww1 and the car and truck industry and a convoy of ww1 cross the country, they are often repeated so may be worth a view

-

On 5/9/2019 at 3:49 PM, Minesweeper said:

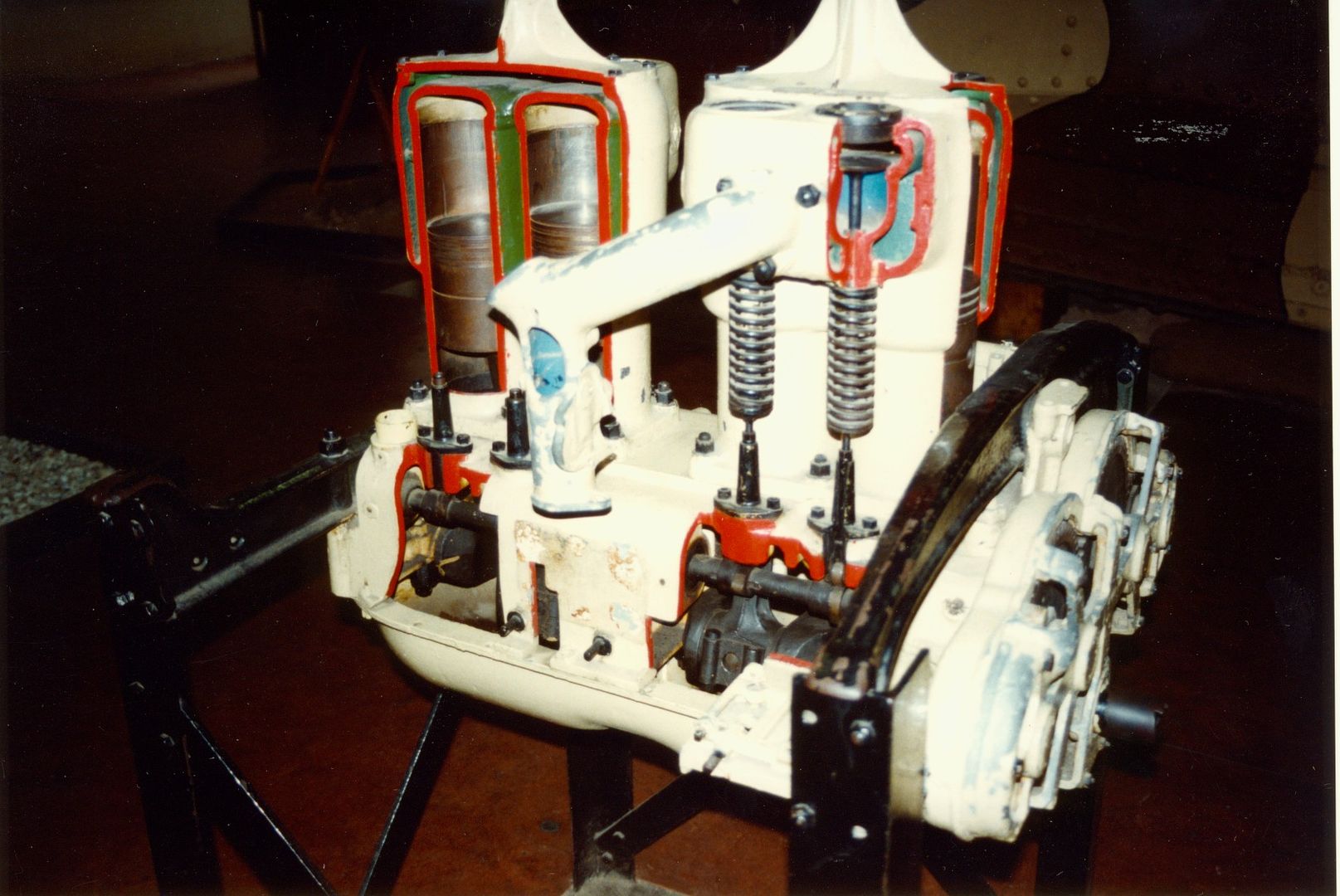

It just occurred to me to check the threads on the studs in the Crank Case which hold the bronze castings down - described in the Parts Book as the "Valve Plunger Guide". Steve took the Bronze Guides off with the Cam Followers still in them - all complete -15 of the nuts came off easily and the last one came out bringing the stud with it.

The studs are 5/16" in diameter I would expect that the TPI on them to be either 18 or 22 - possibly 24 but I guess it will not surprise you now when I found that they are 20 TPI ! I have double checked this by trying 5/16" Whit/UNC/UNF, and BSF nuts on the studs but they do not fit. What am I missing?

What are we going to find when we get further into the engine, I wonder?

Tony

Hi tony

I have shown all this to Father, and he said where we could we used original , but he had to put a tap down through ours and used high tensile screws, 5/16 if this is any help,

-

Father says sand blast the metal liner so the leather will bond to it better, ours is the same, our one was made new to fit with girls punched out , using various local facilities

-

Totally loving this, I think someone will have to visit and see this is going it's good to know that something that was left that long is still good on the inside, even if the outside is not💗💗

-

One step at a time😀 happy New year to you all too 🚚🚚

-

Lots of bits there, I know of some free pensioner labour😂😂😂😂😂😂😂😂😂😂😂

-

Yes they are the same size, it's just the angle and one is minus it's tyre

-

-

58 minutes ago, Old Bill said:

Yes we have that one somewhere, guilty, I'm the one in the middle 11 or 12 I think, and father had hair😆, be careful you could end up with a little helper, and another overseer😆😆😆😆

-

1

1

-

-

On 11/4/2018 at 10:19 AM, Old Bill said:

Thanks for all of your suggestions chaps. Dad has been trying 'Fertan' so I am looking forward to seeing the results. We haven't tried electrolysis yet but it is one to keep up our sleeves. In the mean time, one of the chains has been in the molasses and has come out quite well.

Some of the links are still seized so it needs some more work but it is a good start.

We have been fortunate to have been given another P&H lamp. This is the same as the original pair that we have but has a much better casing so between them, we can make up a good pair.

It is missing the badge but Dad has managed to salvaeg the one on the rotten lamp.

Into the molasses!

The new casing still had some paint on it so the molasses didn't have any effect in those areas and it had to be finished off with a wire brush.

Dad has had some new glasses cut for them.

Meanwhile, we cannot resist having a bit of a go at the job. We have decided that our Christmas project will be to pull the engine out and tear it down as we think that we have just enough space to do that. It is getting tight though!

Tim has taken the bonnet and top hose off and is looking to remove the radiator.

One bonnet catch remained on the chassis. We are going to need eight of these for the two lorries so I foresee some serious filing in my future!

We are going to need an engine stand as well. The Peerless engine sits on the chassis rails rather than a sub-frame so the engine stand needs to be wider. A little modification was therefore undertaken.

Must go and finish the Thornycroft!

Steve

I know a certain someone who's going to be glued to this 😜😜😜😜😜

-

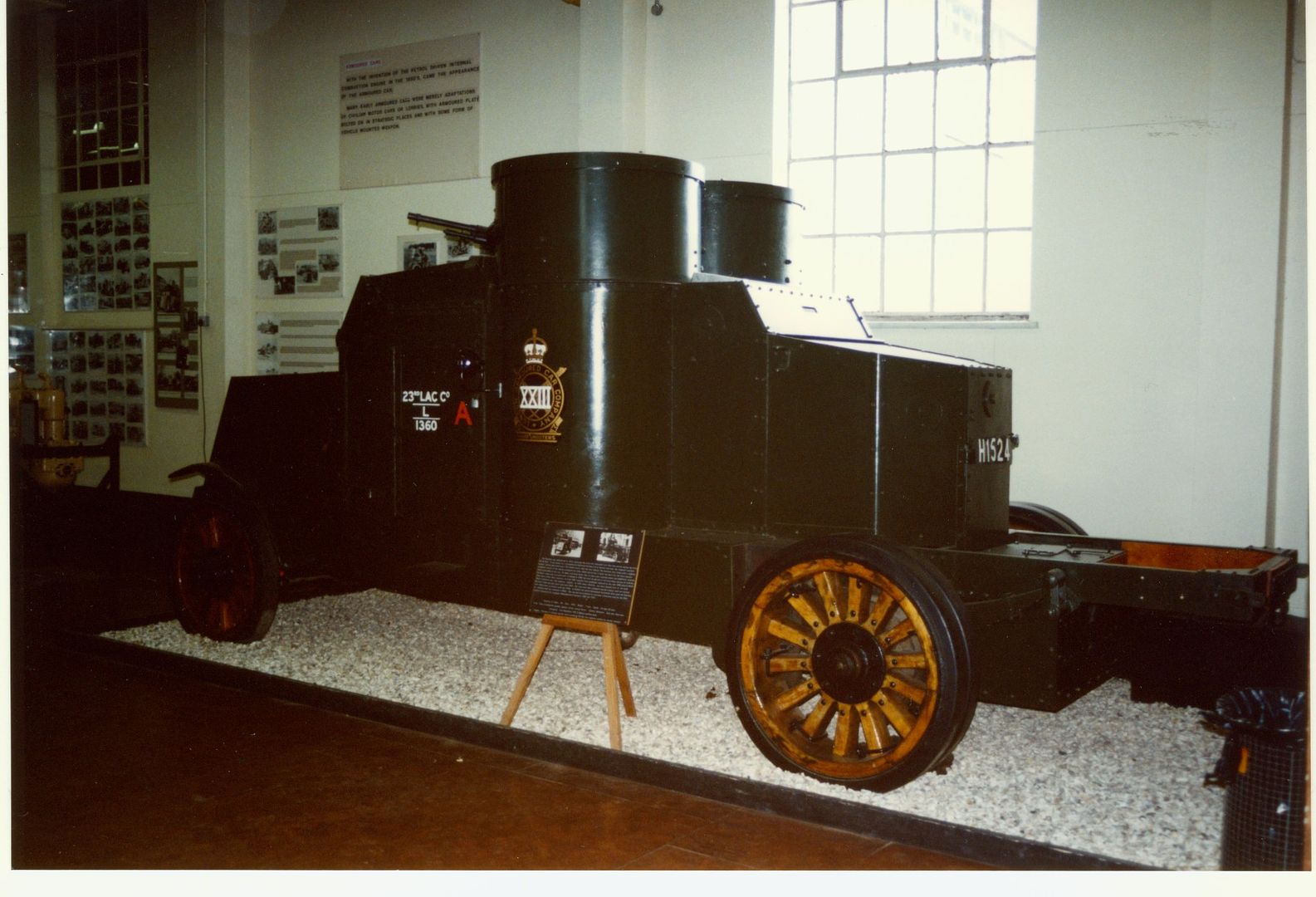

:-D I remember going there with father when he did the museums peerless, great time, it shut for lunch and we were locked in so father could get up close to theirs, great wandering in and out of tanks:-D

-

I have just checked my notes regarding radiator cores for Thorny J types. I came up with a figure of 22000 when looking at the Portsmouth bus many years ago. However, we have had a much closer look at the Carlton Colville lorry and have found that there are 125 tubes which are 23" long between tube plates. The lorry has gills at 5 per inch giving a total of 14375 altogether which will save a few quid. The bus gills are at 8 per inch giving 23000 or thereabouts!

I must talk to a radiator manufacturer shortly and see what they can do for us. Threading the gills ourselves may be a trifle tedious but could save some money. We would then take the tubes back for dipping and soldering into the tube plates. Must get on the drawing board so we can get the brass ordered.

Steve

Father says the peerless is the same 5 per inch, and he also had child labour to help:-)

-

very nice:laugh:

-

Great line up,,,, would be looking even better with appropriate Peerless in the same uniform:cool2:

WW1 Peerless lorry restoration

in Pre WW2 vehicles

Posted

I saw this too, probably isn't the same but you never know with dad he may have seen it advertised, but he did have a lot of interest in gardner engines in general so may be that's where it came from