Jeroen Sleijpen

-

Posts

31 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by Jeroen Sleijpen

-

-

Sorry guys but there was never used a black undercoat!

All factory picture from General motors, DPCD group, white, autocar, federal, mack etc show that the bare metal is sprayed with a red or green oxide primer and recieves its final layer of OD.

The black "glue" jack refers to is typical post war norwegian preservation.

-

there are at least 2 in holland.... and 1 in the uk.... but I don't remember the owners at the moment

-

I know this is a long shot but does anyone know of a surviving example or even parts of one of the following 1940 GMC's....

ACX-504,3 ton 4+2,178 wheelbase.

ACKWX-353.6+6.

ACW.4+4.

Of all these models less than two thousand of each were delivered,they were ordered by the French but France fell to the Germans before they were delivered so the trucks were transferred to the British forces.none are known to survive.if there are any survivors still out there they will probably be just a bare chassis with no or very little bodywork remaining and most people probably wouldn't give them a second look.so next time you are delving about in a scrapyard or find a rusting wreck in a hedge take a closer look!!

Matt.

How can one determine if there are non of those trucks left.... :?

I know of the ACKWX several restored and unrestored examples in the US! and even the ACX-504 can be seen there!

-

AC spark plug manufactured a lot of items during WWII like your cap but also .50cal machine guns air craft parts several truck parts and ofcourse sparkplugs!!!

-

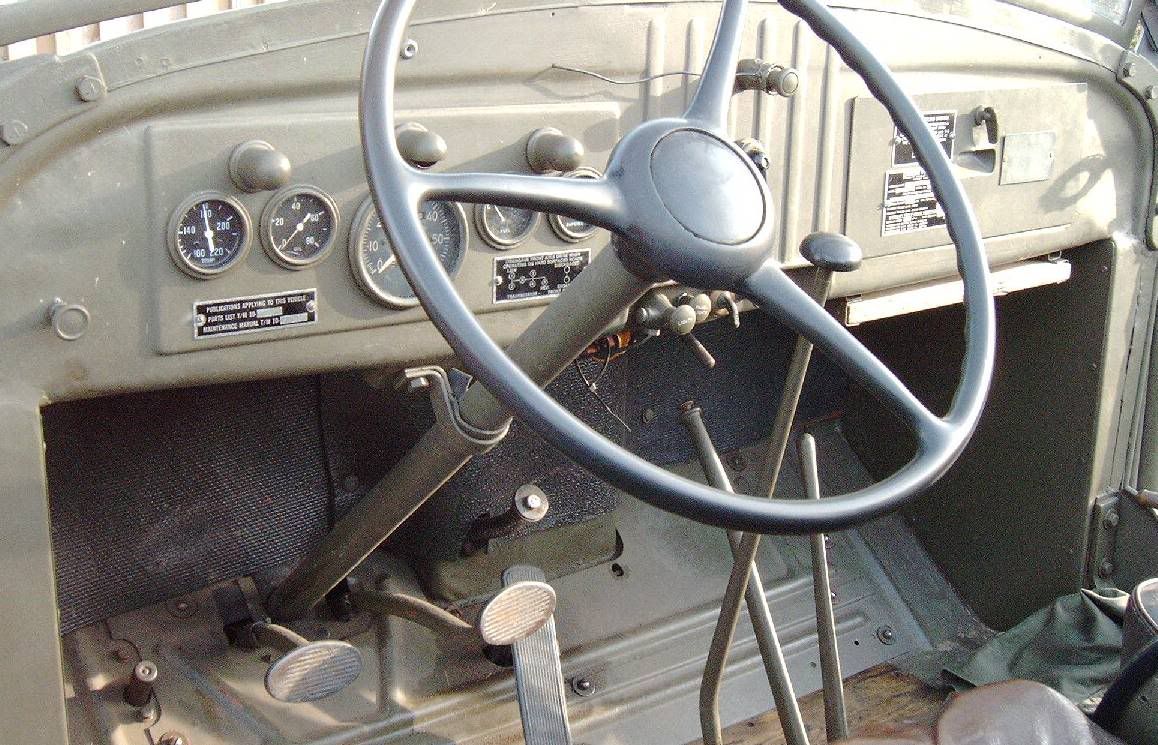

take out floor in the cab

take out the propshaft between box and case

take out the speedo cable

loosen the crossmember and slide to the rear.

take out the pto in case there is one

then put jack under the gearbox

release all bolts and slide box to the rear.

realy one of the easiest trucks to remove the gearbox... much easier then a jeep!!

-

make sure when you take the top of that all of the gears are still in good shap and not missing any of their teeth. when one brakes of the gear it can cause the trouble that you have

The clutch can only be a problem if you select a gear not if everything is in neutral!!!

take of the top and put the gears in neutral bij hand. if one of the gears is still driven then take the box out and rebuild. easy job!

-

just wanted to add a WC to this forum...

this is mine at the backcover of a army motors magazine....

-

strange.... because you are doing everything just fine.... only thing I did was copy paste the link you wrote in your last post...Seems to be that for some reason you can't post pics.... :shock:

-

Thanks for the great photo of the M3 Grant. This winter we are hoping to fit a 37mm gun into the turret, fully fix the hull roof in place, fit a prop-shaft guard, change the clutch release springs for more user-friendly ones, mend the engine oil leak and provide proper access ramps or ladders for veterans to get in and out. We may also fit a basket under the turret hatch to enable people to ride safely in the turret. The correct aircleaners may also be obtained and ftted if time permits.

Thanks for showing us this nice piece of history John!! I realy liked it.... Keep us informed about the progress you are making!

Jeroen

-

Hi Jeroen how ya doin......i am still lookin good in the top of Kevins M4A3 E8...... :lol:

Regards

Lloyd

doing fine Llloyd thanks! working on several Macks now... :shock:

anyway how is life across the channel?

-

.........is this to good to be true?

nope....that is mechanical enginering! and fixing it in the right way:D:D:D

btw... you were talking about a guy named Joel...I don't see a post of him...or am I missing something...?

-

Hi Jeroen.

Thanks for that mate, but where is the bleed screw on the Hydrovac as Joel was saying that you have to bleed this first?

there are 3 types of hydrovac used on the GMC and even an booster on the early ones.

Not all of the vacs have a bleedplug... Because of the high pressure that the hydrovac is creating on the brakesystem, you only have to wait a few minutes and then bleed the wheelcyl.

Cheers!

Jeroen

-

Jack.... refill the master cylinder again. put a few drops of engine oil in the vacuum chamber of the hydrovac.

Then start the engine.... you will see that the majority of air will come back to the resorvoir of the mastercyl.

then bleed them the old fashion way.... pressing the pedal few times. hold it under pressure when there is resistance and a helping hand bleeds the brakes one by one starting with the longest line from the mastercyl.

keep the resorvoir full at all times.

The thing that happened to your truck is that a small amount of air came in the line to the hydrovac cylinder. this causes the brakes not to work.

-

Corné the pics you show us is a Airborne CCKW 353 cargo truck Not a dump truck.

Jack as far as I know only open cab trucks where build in an airborne conversion...So probably the dumptruck you are talking about fitted with a hardcab after the war!

Can you get the chassis number?

Jeroen

-

Thanks for that.

Is it of WW2 vintage?

jeps.... this is WWII vintage... but often installed after the war!

-

Found it in northern France... It served in british service....

It was made on my birthday!!! the 29th of june... (not DOD)

Will keep you informed of the restoration!

Jeroen

-

Hi Jeroen.

Wonderful pictures! What a handsome looking truck that Mack is 8)

Good to have you here!

Jack.

Thanks mate!! great to have a new forum up!!!

Cheers!

-

-

nope.... I tried several JPEG smaller then 6kb from my pc.... but still errors...

-

WWII Reeves manufactuar.... but what year exactly.....????

-

Has anyone found a source of new 900 x 16 bar grip tyres suitable for British pattern rims?

Dave contact Joop Staman http://www.jeeparts.nl/

He had brand new 9.00x16 bargrips selling them for US dodge rims but they are British rim size!! to large for US rims....

-

I never use adds in the fuel... we have unleaded fuel with an octane rating of 95 over here.

A friend of mine develops engines for Ford, He told me one that it is not important to use any adds for our "leaded" engines while they don't make high revs... He told me that it is only important for cars that make high revs like a MG sportscar wich is running 6000revs...

-

never counted them... but the M32 is sherman based...and M4 Highspeed Tractors.... use sherman parts....

pffff to much....

-

Jack what we have here is an manual electric trailer brake!!!

When your truck was used to pull a electric braked trailel eg a M14, then you could brake the trailer alone going down steep hills or brake together with the hydraulic brakes on the GMC.

Your M3 halftrack has an electric brake as well...this one is working with a mechanical delay when you press the brake pedal.

the 4th wire on your trailer connector is for this electric brake! The black knob is to adjust the sensitivity of the brake according to the load of the trailer. This knob is on the dashboard of your halftrack!

So not all of the CCKW's where equiped with this feature!

GMC chassis..colour?

in American Vehicles

Posted

Remember that the GMC CCKW truck was assembled from different factory production units. the black you talk about is a transport protection coating.

Remember also that directly after the war all vehicle units went back to motorpool units for repair/overhaul and from there directed back to units or lend lease programs. So sure thing that also your 2 dodges are rebuild somewhere in the past 60 years.