-

Posts

264 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Blogs

Events

Articles

Store

Downloads

Posts posted by flandersflyer

-

-

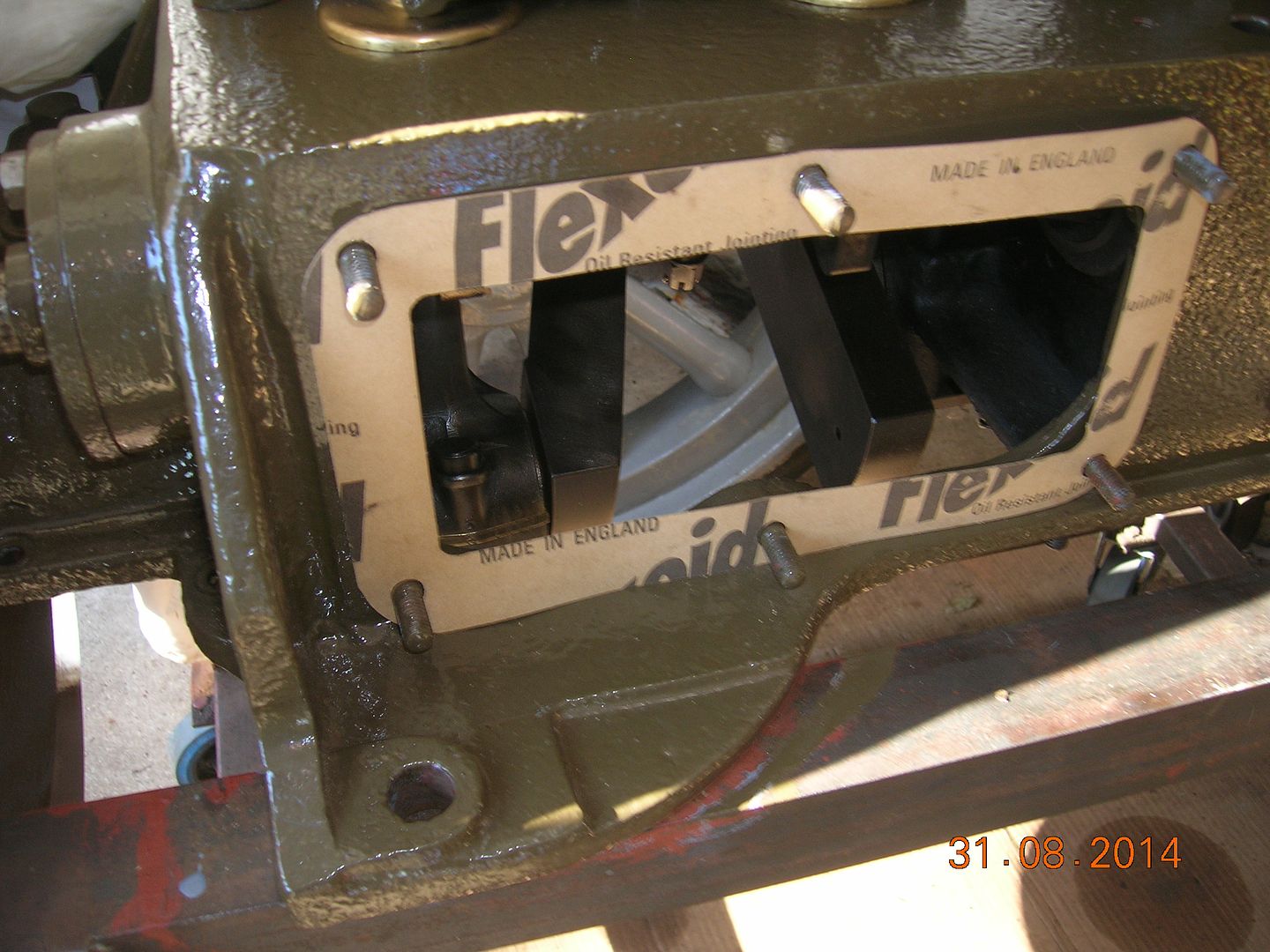

yep...Repair to cast ally[ATTACH=CONFIG]95886[/ATTACH][ATTACH=CONFIG]95887[/ATTACH] diff cover using some of that amazing repair rod you can see at model engineering shoe etc. I made asheet copper mould around the area that was missing. I used a mapp gas torch to heat it. I was very dubious as to it working but it was fine. I did try tigging it but 100 year old ally is awful.[ATTACH=CONFIG]95885[/ATTACH]forget using argon on old cast or ally....its full of impurities...so it either just blows away or gasses up......

-

-

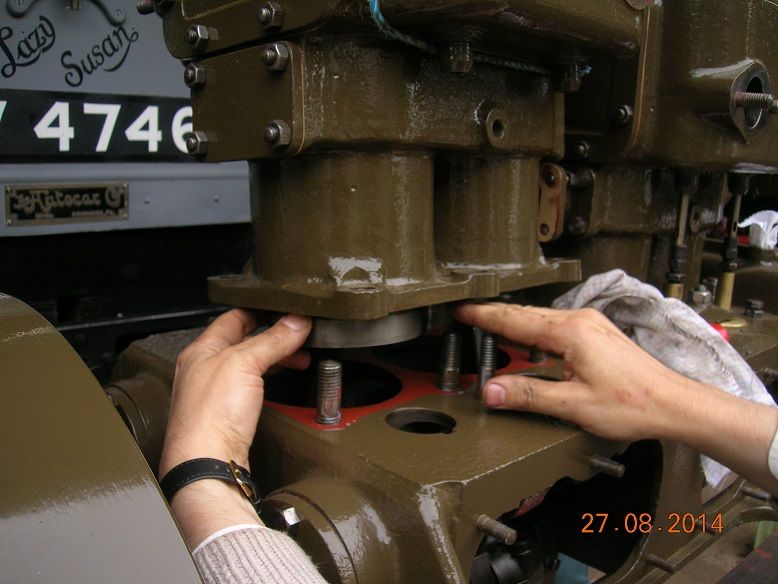

We have had a family get-together in Devon to take the lorries to Honiton Hill Rally and also visit the Great Dorset. In between times, we have found some time to put some more of the engine together. The first block was fitted in January but the other one has been sitting on the floor ever since! Steve had scraped in the big ends a while back so we were ready to fit it.

Step one was to dust it all off and then oil the pistons and bores.

Then, using the trusty chain block hung from the door frame, we lifted the block and gave the water connection a liberal coating of Red Hermetite which is, sadly, no longer available.

Then it was simply a case of lowering it onto the pistons whilst Steve compressed the rings into the bores.

i still have a pot of stag..someware....

anyway....what i like about this thread is the way progress is in trunches...like installments....

it allows us all to scroll through....then await the next episode..

riveting stuff boys...crack on...

-

interestingly you notice how the aircraft is actually constructed only when the fabric is off...

the Camel is built using solid wood spars machined out at regular intervals to reduce weight.

it utilises extensive `stringing` throughout...these wires are streamlined....

further more, it uses small metal brackets to support the joints in the wooden fuselage framework..these brackets also have little `eyelets`...for the stringing to attach to...

now...compare this with its adversary...the Fokker DR1

for a start the DR1 uses cantelever wings...the interplane struts are only there to reduce vibration..

theres none of the extensive wire bracing either....that could always be caught by a bullit

further more the DR1 has a welded tubular (Reinholt Platz) fuselage...with wire bracing support...

so...which is the more advanced aircraft?...

-

yep...Yes the Batley built example was being built by the Northern Aeroplane Workshops for the collection after the triplane and M1c they'd produced for us, the camel has come down for final work and covering and sadly the NAW have ceased building aircraft as they don't feel they have another 10 year project in them. The Brooklands Camel has been up a few times now and some of the collection's exhibits will be heading south for their displays. The Brooklands Camel did successfully run once during the day and we swiftly got it away as the heavens opened once more. Here is a picture from the top of the B type bus of the two camels in hangar 1 at the end of the show.[ATTACH=CONFIG]95467[/ATTACH][ATTACH=CONFIG]95468[/ATTACH][ATTACH=CONFIG]95469[/ATTACH]

Cheers

Steve

caus they wanted me to make up a load of the metal brackets for sopwith type aircraft.....

they were on about doing a DH2 as well.....

dont know if this ever got started....theres one with a warner scarab....

i think the idea was to fit the one they intended to build with a gnome....

where did northern airoplane workshops end up?...as i had it that they were being forced to move from Bradford road...

(i live in Dewsbury (south leeds) by the way)......

-

i thought it was scandinavian for value....NETTO means all up price with their version of VAT LOL :nut: Jarek would be prepared to haggle

-

just in Batley they were building a sopwith camel...i saw it without any of the fabric on it...

when i asked about it i was informed it was being built for the shuttleworth collection....it was to be fitted with a clerget rotary....

-

Well i used to work as a plater/welder...before i went back to college (electrician)...

i say well done for getting the workshop in shape, kitting it out and getting on with it...

it should all come together....

-

Thanks John - something else to consider! As you will have gathered, we do like to use the original parts as far as possible so we will not give up on either set just yet. We will get them off first and have a good look at them before finally deciding!

Tony

If you were to use both types in service you will find the cast ones perform better.

The presseds steel ones will distort in use, which doesnt help efficiency.

The iron ones will be stiffer and will not distort to the same degree.

Iron will soak the heat away better....

-

well...i have aI think that Flandersflyer might have been intending to joke about the Stihlsaw, but actually I have found that you can be really controlled with one. It's a bit like cooking where a big knife is more controllable than a small one, the inertia of the tool can be useful to control twitchiness.I get really quite good at cutting out stone mullion windows with a Stihl saw in a previous project. If I still had one I suspect that it would have been my go-to tool for the angle iron here.

stihlsaw that i use for general work...like getting through concrete rafts & the like so i can get armoured subs in the ground..(i`m an electrical contractor)...

it comes in as well for cutting large section armoured & SY cable....

-

either that or a stihlsaw....I agree that a plasma cutter is probably the best way of cutting bites out of a piece of angle and lots of other profiling and cutting jobs. The problem is that you do need quite a big compressor as well, probably big enough to run a blast cabinet which would also be very usefull. I think most people can't justify this level of plant but I must admit that a 9" angle grinder with a thin cutting blade would have considerably reduced the chain drilling and the subsequent tidying up. Then again most people have neighbours that don't appreciate the noise of angle grinders. Back to chain drilling then :-(.David

-

When Can I pick up the Dv11 that is lying around, I have transport!

I now have Dv11 plans and I am studying them!

Will also investigate the fuselage mentioned to be in Germany

Thanks

Tom

there were several different factorys instructed by the German high command to start building Dv11 type aircraft.

One of course was the fokker works

another was the OAW plant..(although OAW didn`t actually build any complete aircraft)

the other was fokker`s great rival:

Albatros

the fokker built Dv11s were considered inferior in both quality of construction & materials to the other examples as the schwerin works struggled to keep up with production....about 3500-3700 examples were built between the late summer and autumn of 1918...

most Dv11 types soldiered on with the old Mercedes D111..in its overcompressed and other modification forms...but it was with the new BMW 111 that the Dv11 really shone....

there were no actual plans sent from Fokkers to the other companys instructed to start production....what fokkers would do is send a complete airframe for the other constructors to copy...for this Anthony Fokker got a 5% royalty on every complete aircraft produced by his rivals/competitors

this also meant that an aircraft produced by...say Albatros would not be entirely the same as one from Schwerin....

so plans would have to be altered/modified to suit....

-

why not just burn it out with the bottles?If I played your game I think I would have been unable to resist buying a plasma cutter.Even though I don't play your game, I still keep nearly buying one.

if you use the correct nozzel ...and get the gas/oxy set rite....then it will fly through lovely...with just a bit of fluff to click off with the grinder afterwards...

-

A lot of the late Mr. Dibnah`s machines were on linedrives.

That place of his should`v been kept as a museum....i think it was all sold off after his departure.

very sad.

-

i remember an old Sagar bandsaw that was just stuck outside in a yard in Hereford where i did a blacksmithing course 15 years ago...

it was all open framed...cast...

would`v been run off linedrives would that.

Another place to see old machinery is the national coal mining museum at Caphouse colliary between Wakefield & Huddersfield...theres the old Machine shop there with a load of old line driven stuff like bandsaws, table saws, planer/jointers and spindle moulders...theres also a load of old line driven lathes, millers and grinders...theres an old line driven box & brake radial drill there as well....

-

is all this Achim angels planes that he has built?

-

here is a good example of the fokker Dv11:

here is the same owner/pilot...with his fokker DR1:

-

the old rhinebeck has 2 D7sThat Albatros looks lovely - they've done a brilliant restoration job on it considering its age and use since Cole Palen built it. A pretty thing, but that wing would terrify me. When they need to put extra struts on the struts to stop the wings fluttering that's never a good sign

I've yet to visit Old Rhinebeck in person (one day!) but I've heard their DVII is particularly authentic, and so would be a good one to use as a reference. Unlike the Albatros it has an original engine doesn't it?

If you are still wanting to use the shot down Wusthoff plane as a reference point, it's worth checking out the Wingnut wings model kit website - Wingnut are owned by Peter Jackson and informed by his collection of replicas and originals, and they have a lot of reference photos on the site. A couple of these are alternative views of that Wusthoff Fokker, showing the plane and trailer in different poses. I hadn't seen these pictures anywhere else -

http://www.wingnutwings.com/ww/productdetail?productid=3081&cat=1

one flies with a Mercedes D111 `overcompressed`

the other has an inverted gypsyqueen.....

-

The Albatros scout was the first of a new breed of biplanes to utilise the Mercedes D111 6 cylinder inline watercooled engine that the Luftstreitkrafte had hoped to regain air superiority with over the western front towards the end of 1916. This aircraft type was largely responsible for what became known as `bloody April`...where the German air service took a terrible toll of inferior allied types during 1917. The mercedes D111 engine had been in existance from 1914 but had been considered too powerful for the very eary aircraft types. This was a 6 cylinder inline with exposed rockers operating directly from an overhead camshaft and developing 160 HP. There were various upgrades made to this power unit to keep it competitive with newer allied types entering service but by early 1918 it was considered outdated. Early versions had the oil sump cast with a centrally mounted oil pickup and cylinders that were in pairs. Later versions of this engine had seperate cylinders and a rearward sloping oil sump with rear mounted oil feed. This was driven from a quill shaft that also drove the dual bosch magnetos, an air pump for pressurising the fuel tanks and also of course the overhead camshaft. There was a lever that could be used for manually de-compressing the engine to aid startup...this worked by rotating the camshaft slightly..thus opening the valves a little. These were considered high compression engines for the day. Starting could be either by hand over compression or by a hand operated bosch starting magneto within the cockpit. The airframe was made up of a thin gauge plywood shell....very rigid & strong...which is unfortunately more than can be said for the single spar wings (hence the small angled strut brace that can be seen on the forward edge of the lower wing). There were several incidences of the leading edges of the lower wing collapsing on the albatros scouts during steep dives...or harsh manouvering during combat. This was a problem not suffered by the Pfalz D111 hence the reason the pfalz was considered more suitable for ground strafing and `balloon busting` duties. The Pfalz used the same power unit as the albatros as did the Fokker dV11 (in its later `overcompressed` variants)I do not think the dynamo can be converted to as starter without major changes as the windings are completely different.Here is an Albatross at Old Rhinebeck which I saw during a visit on Saturday when I went to look and photo graph the detail of a Fokker DV11.

[ATTACH=CONFIG]92133[/ATTACH]

Most of Manfred von Richthofen`s 80 confirmed `kills` were acheaved flying the Albatros. The gaudy paint schemes adopted by many of the pilots of the jastas led to the nickname `flying circus`.

There are several short videos on Youtube of replica aircraft flying with original Mercedes D111 engines.

Here are some images of the engine showing cylinder arrangements and valves etc:

-

theres one in the US with a 160 gnomeBut then Fokker had a financial incentive to use the rotaries as he'd bought the company back in 1916

Actually a non-flying 'flying razor might be an easier build than a DVII. Smaller, probably easier to construct, easier to rig the wing if you want to show it intact. There have been a number of recent flying replicas of the 'razor' and in the same way as the others there will be plenty of 1/4 scale RC plans around to give you an idea of how easy it will be to build.

On the other hand the DVII has the mentioned-in the-armistice kudos, and the particular one in the picture does have a story with it - http://en.wikipedia.org/wiki/Kurt_W%C3%BCsthoff.

On a totally different tack, there may be full-size replicas out there, but just not of a DVII or DVIII. A couple of recent films have seen prop replicas built for ground scenes - 'Flyboys' and 'The Red Baron'. The props from the first one ended up in the Manston history museum.

The Red Baron was a German production, and it did not break any box office records. I got the DVD and one of the features was on the number of 1:1 scale albatrosses and Fokker Dr1s they made.

It might be worth an email to the film company:

http://www.german-films.de/filmarchive/browse-archive/view/company/company/niama-filmstuttgart/

to check whether they have something sitting in a warehouse that would save you the hassle of building your own.

it was built for Kermit Weeks.

-

It smacks of desperation, but I am having decent results with my current restoration (not miliatary, not truck) filling in rust pits with TIG and grinding back.

(if anyone is interested in a off-topic restoration, http://bodgesoc.blogspot.co.uk/2014/04/1921-ner-car.html

I plan an update tonight. Err, this morning)

what you using?

De-oxidised stainless rods?

weld cast lovely with the argon set will stainless...

-

There seems to have been quite an interesting effect with the 'outsourcing' of engines - the Thulin engines are an example of better workmanship, but there were lots of problems in other companies when engine volumes ramped up and outside manufacturers were involved.

Some British-made Clergets apparently didn't perform nearly as well as French-made ones, whilst others were fine. Some French licence-built Hispanos were apparently terrible and downright dangerous, but engines from the original company were fine.

It must all have seemed a bit of a lottery to the pilots, and since engines wore out much faster than aircraft the supply implications must have been interesting! One of the German Aces had a standing reward of wine for anyone who'd bring him an intact French engine for his Dr1, but this was as much to do with the phasing in of the Mercedes-engined DVII and resulting lack of any spare rotary engines - German, Swedish or French!

there was a surplus of rotarys in Germany

their time had come to an end really and there they were...just sat there with no use for them....this is why the Fokker DV111 was developed....a single cantelever wing....(less drag)...and a thin section fuselage...(again, less drag)...this earned it the nickname :

`the flying razor`

-

the Gwynne manufactured Clerget`s were outstanding.There seems to have been quite an interesting effect with the 'outsourcing' of engines - the Thulin engines are an example of better workmanship, but there were lots of problems in other companies when engine volumes ramped up and outside manufacturers were involved.Some British-made Clergets apparently didn't perform nearly as well as French-made ones, whilst others were fine. Some French licence-built Hispanos were apparently terrible and downright dangerous, but engines from the original company were fine.

It must all have seemed a bit of a lottery to the pilots, and since engines wore out much faster than aircraft the supply implications must have been interesting! One of the German Aces had a standing reward of wine for anyone who'd bring him an intact French engine for his Dr1, but this was as much to do with the phasing in of the Mercedes-engined DVII and resulting lack of any spare rotary engines - German, Swedish or French!

the problem with the Clerget was that it used a brass `obdurator` ring...this was fitted around the piston skirt....

when this overheated...(which it often did)..it would crack.

this then allowed the hot gasses to travel down the piston skirt turning the cylinder a blue with the heat.

cylinders that had this blue had been heated to something like 350 *C

as for the french Hisso`s...i think it was a case of:

"get as many units in airframes...and to the front as quick as we can"....lets face it...most of the aircraft wouldn`t last long anyway so...

the british version you refer to was the Wolsley Viper

it didn`t share any common components with the Hispano suiza

the Viper was for its time the best power to weight ratio of any power unit on the western front....

the most famous aircraft to use it was the Royal Aircraft Factory SE5...and SE5a

-

I say chaps, surely you mean the Oberusel Le-Rhone copy, what what?

trevor

there were a few differences between the oburusal and the Le-Rhone

the Oberusal had a cast crankcase...the Le-rhone`s was forged then fully machined throughout...

the Le-Rhone was generally better finished...Oberusal rotarys were made under licence by the thulin firm in Sweden...these were better than the Frankfurt Oberusals and were highly prized by pilots

One of the finest rotarys was the siemens halske...but they couldn`t get it to run rite..(that was the one with the contra-rotating crank)...gave the siemens shukert S111 a fenomenal climb rate...and higher ceiling than any allied type then in service

Fiat 18bl at Stow Maries Aerodrome

in Pre WW2 vehicles

Posted · Edited by flandersflyer

heres some bumph if you want to get into home casting:

http://www.backyardmetalcasting

http://www.instructables.com/id/Backyard-Metal-Casting-and-Homemade-Forges/

http://www.flamingfurnace.com/2012/11/foundry-setup-crucible-flask-and.html

http://www.myhomefoundry.com/

http://www.alloyavenue.com/vb/showthread.php?7812-Making-money-from-backyard-metal-casting

http://www.themetalcasting.com/hobby-foundry.html

theres plenty in there.....goes into aluminium and brass...theres stuff on iron...and your gunmetals etc...

shows you how to set up a home foundry...good for small batch specials & one-offs

pattern making as well....although i think what Steve has acheaved in the Dennis thread was outstanding...